I'm back on night duty tomorrow night so I have a little free time.

No need to data base, just bookmark the Falcon Six Performance book, and list this as relevant detail.

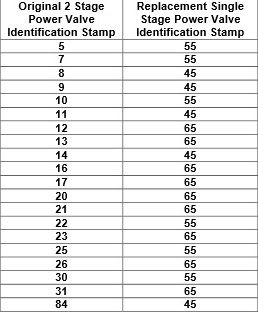

There are still about 23 different 2 stage power valves in common production, including one fully adjustable 2 stage from Mikes carbs.

Holley set a truck like 14 pounds per cube limit before you really needed to consider a 2 stage power valve. It was based on the idea that frontal area would also go up from about 20 sq feet in a little Falcon or Mustang II to about 40 sq feet in an E 250 truck. Low power to weight vehicles benefit from being able to lean off the richness in slow, ambling load conditions. So two stage carbs were birthed in the economy verses emissions era, and the 14 pound per cube idea played out like this...

6440 pound shipping weight 460

6006 pound shipping weight 429

5600 pound shipping weight 400

5180 pound shipping weight 370

4900 pound shipping weight 351

4220 pound shipping weight 302

3570 pound shipping weight 255

But the lighter 1983 to 1985 5.0 Mustangs, Capris and 1981 to 1988 5.8 F150 and Bronco trucks were 10 pound per cubes on some versions, and gained exceptional verve and fair economy with a 2 stage power valve 4180 or 4190/4195 Holley carb. So did the 2-bbl 2150 1.21 carb in the 1982 5.0 Mustang GT, and the odd 2150 equiped 400 Bronco or F150's. Jet sizes in big 2150 carbs were squeezed right down to F56 in 2-bbls and H62's in 4180C 4-bbls.

Even below 14 pounds per cubic inch recommendations Holley set, FoMoCo found the 2 stage power valves allowed base jetting to be leaned, and the large V8 style Power Valve channel restrictions left to enrichen 8 jet call sizes.

14 pounds per cube is a 170 2380 pound Round Body Falcon,

a 200 cube a 2800 pound Fox body Zephyr, Fairmont, Capri or Mustang,

a 250 cube 1968-1973 Fairlane, Ranchero or Torino, or 75-80 Granada/Monarch.

A 79 or 82 5.0 Mustang can have as little as just 9 pounds per cube to lug around, and gets better economy and drive-ability with the two stage power valve; they kept it right up until the last carbed 5.0 V8 in 1985. The two stage PV is just an added bit of extra tuning to the whole kit. Ford found the 255 engine saved 1.5 mpg, but the 1982 5.0 gained 35% more power with a 1.5 mpg highway gain at 55 mph; no mileage penalty, and much of that was the ignition, power valve and gearing. So the annular booster 2150 and 4180 carbs with those valves were exceptionally distinguished economy engines, as well as being quite exceptional performers.

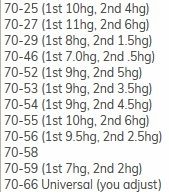

P/N, 1st Stage Opening, 2nd Stage Opening, and any known 1st stage restriction

Holley Lists 3 now, down from 7 a while ago, down from 21 a long time ago.

125-206 12.5 Hg 5.5 Hg .028, like the old Holley PN 2-4311 (later 25BP-475A-12)

125-207 10.5 Hg 5.0 Hg .021 like the old Holley PN 2-4312 (later 25BP-475A-25)

125-208 10.5 Hg 5.5 Hg .028

Others

125-213, 11.5, 5.0

125-212, 12.0, 6.5

125-215, 10.5, 6.0

125-218, 11.0, 5.5 (23 means a 125-218 )

Holley had 21 total if you include the unlisted 24 we found lurking under the hood of an 83 Mustang 5.0 GLX

Examples:-There are date prefixes before the Holley 2 stage call number

A6-

7 Stock AMC 304 Motorcraft 2100 1.08 model 5.5

8 '85 Capri/Mustang 5.0 Holley 4180C stamped "8", means the 2nd stage would come in at 4.5

B1

8 Ford 460 F250 4X4 with 4180c come in at 4.5

13 On some IH 2300C truck carbs come in at 6.5

16 carbs with this PV come in at 6.5

23 = 1984 Capri/Mustang 5.0 Holley 4180C F1 23, or 125-218, 11.0, 5.5, but says it comes in at 6.5

24 = 83 Mustang 5.0 GLX 5.0 not on list

Standard rebuild Capri/Mustang 5.0 Holley 4180C 3-1346 kits = 10.5/6.5, no traditional stamping

MIKES Carburettor Parts Has 11or 12 generic Number:70-1000 2 Stage Power Valves

Napa offers a total of 8 diff. 2-stage power valves.

PN 2-4311 1st stage opens @ 9.0"Hg, 2nd stage @ 2.5"Hg 1st stage restriction .035

PN 2-4312 1st stage opens @ 10.5"Hg, 2nd stage @ 5.5"Hg 1st stage restr. .021

PN 2-4405 1st stage opens @ 9.0"Hg, 2nd stage @ 2.5" Hg 1st stage restr. .028

PN 2-4406 1st stage opens @ 10.5" Hg, 2nd stage @ 5.0"Hg 1st stage restr. .020

PN 2-4409 1st stage opens @ 11.0"Hg, 2nd stage @ 7.5"Hg 1st stage restr. .028

PN 2-4410 1st stage opens @ 10.5" Hg, 2nd stage @ 5.0"Hg 1st stage restr. .028

PN 2-4412 1st stage opens @ 11.0"Hg, 2nd stage @ 6.0"Hg 1st stage restr. .0225

PN 2-4413 1st stage opens @ 11.0"Hg, 2nd stage @ 7.0"Hg 1st stage restr. .024

Ford

had five Motorcraft 2150 2 Stage Power valves from 1974 to 1979. Since it has a wide range of crack off vacuums, I've listed them as Nominal so you can determine the pattern in power valve rank.

CE105 Nominal 7.0Hg/ 2.0Hg

CE120 , CE123 & CE122 Nominal 7.0Hg/ 2.0Hg

CE126 Nominal 10.0Hg/ 3.5Hg

CE130 Nominal 10.25Hg/ 5.0Hg

CE132 Nominal 10.25Hg/ 6.0Hg

Originally Posted by #26 by xctasy » Tue Dec 13, 2016

Connect With Us