Those long awaited head flow figures. I knew they would be in one of my 35 boxes of Engineering manuals. From three sources.

1. Essex V6 Stan Weiss from his World Wide Enterprises showed little illumination to the existing figures from

2. Peter Burgess and David Gollans "How to Build, Modify & Power Tune Cylinder Heads", a Veloce Publishing PLC book first published in 1997.

Stan W has intelligently rescaled the 25"H20 UK flow figures from this publication to suit the 28" H20 SF flow bench rating convention. Any one understanding the diffrences between US and UK flow bench certification in accordance with European and British standards will understand why there is a 5.6% uniform difference between the figures quoted on page 85 of Burgess and Gollans book. Sadly, there are no exhaust figures.

3. The figures for the Cologne US market 2.8 are using the US flow bench, and were around all the time, I just hadn't found them again. Bill Jones from Salt Lake City, in Utah, you da man!

Porting the US market 2.8 head is a nightmare, same as the Essex 60 degree UK engine. Both intake and exhausts are variable, thin, and easily broken into

All measurements taken at 25"H20, with bare castings, no manifolds

....... Stock US (74-83)........

Modified US (74-83) .... Modified US (74-83)....|....... Stock Essex 60 UK........... Modified Essex 60 UK

........2.8 6 port head...........

2.8 6 port head................2.8 6 port head .......|.....3.0 D port head (73-81)..3.0 D port head (73-81).

........ Std 1.565 " Inlet.......

Ported with Stock.........Ported with Pinto 2000..|........ Std Inlet..............Ported with Pinto 2000 1.75 " Valves

..........................................

1.565 " Inlet Vales.........1.655" Valves ...........|.....92-109 BHP SAE Net........BHP Not Tested.....BHP Not Tested........| 138 BHP DIN net 220 BHP DIN Net

. | 110 RWHP (Manual) 175 RWHP (Manual)

. Lift

. (thou')

. 50 22

24.5 27 | 19.3 23.4

. 100 44

49 54 | 39.7 (42) 46.4 (46)

. 150 65

72 78.5 | 60.2 69.1

. 200 86

95 103 | 76.6 (81) 89.7 (95)

. 250 99

109.5 116.5 | 89.2 108.4

. 300 112

124 130 | 94.9 (100) 124 (131)

. 350 115

127.5 132.5 | 98.7 136.8

. 400 118

131 135 | 101.1 (107) 143.6 (152)

. 450 | 103.2 148.7

. 500 | 104.0 (110) 152.1 (161)

For the exhaust:-

-

. Stock US (74-83)

Modified US (74-83) Modified US (74-83) | Stock Essex 60 UK Modified Essex 60 UK

. 2.8 6 port head

2.8 6 port head 2.8 6 port head | 3.0 D port head (73-81) 3.0 D port head (73-81)

. Std 1.565 " Inlet

Ported with Stock Ported with Pinto 2000 | Std Ex Valves Ported with Pinto 2000 Ex Valves

.

1.268 " Exhaust Valves 1.417" Ex Valves |

. 92-109 BHP SAE Net BHP Not Tested BHP Not Tested | 138 BHP DIN net 220 BHP DIN Net

. | 110 RWHP (Manual) 175 RWHP (Manual)

. Lift

. (thou')

. 50 17.5

19.5 24 | NA NA

. 100 35

39 48 | NA NA

. 150 50

53.5-57 (All vary) 57.5 | NA NA

. 200 65

68-75 (All vary) 87 | NA NA

. 250 72.5

74-80.5 (All vary) 98 | NA NA

. 300 80

80-86 (All vary) 109 | NA NA

. 350 82.5

82.5-88.5(All vary) 109.5-114 (All vary) | NA NA

. 400 85

85-91 (All vary) 110-119 (all vary) | NA NA

. 450 | NA NA

. 500 | NA NA

For cams, see page 15 or 56,

http://www.pipercams.co.uk/pipercams..._catalogue.pdf

For head porting, see

http://speedtalk.com/forum/viewtopic.php?t=6210

and

http://www.therangerstation.com/tech...ad_porting.pdf

For rebuilding post 1982 Euro engines, see

http://faq.ford77.ru/pdf/scorpio/1245-02c.pdf

Reply With Quote

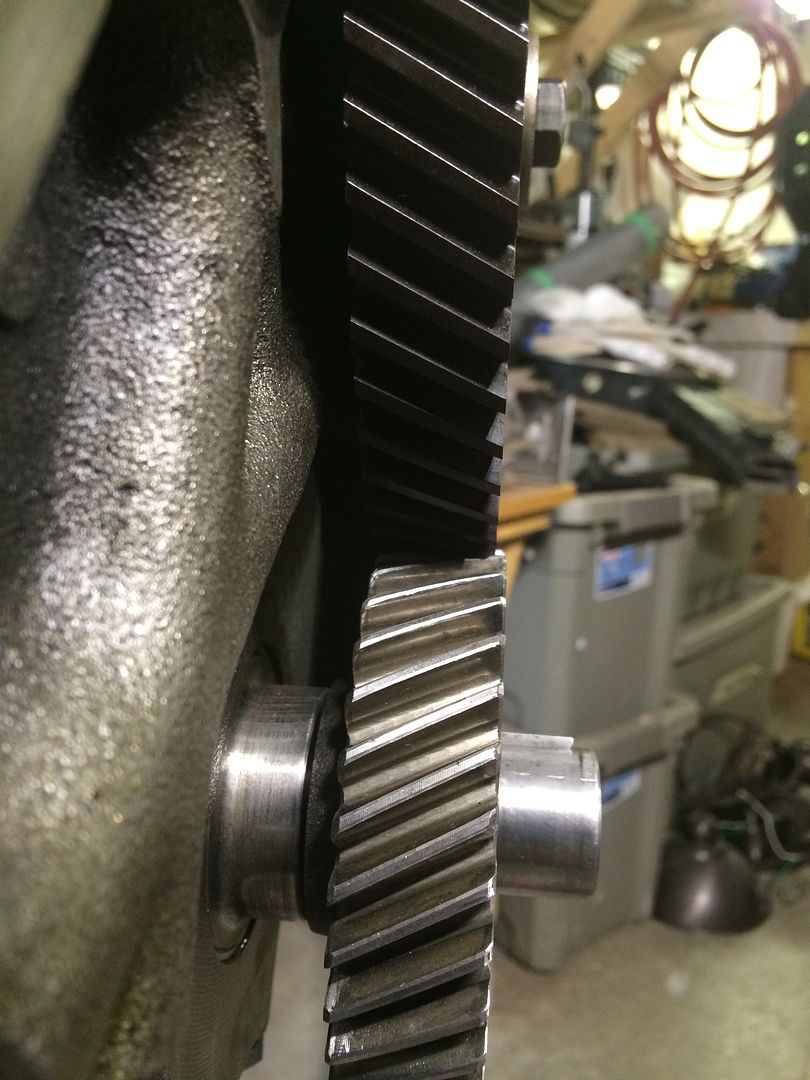

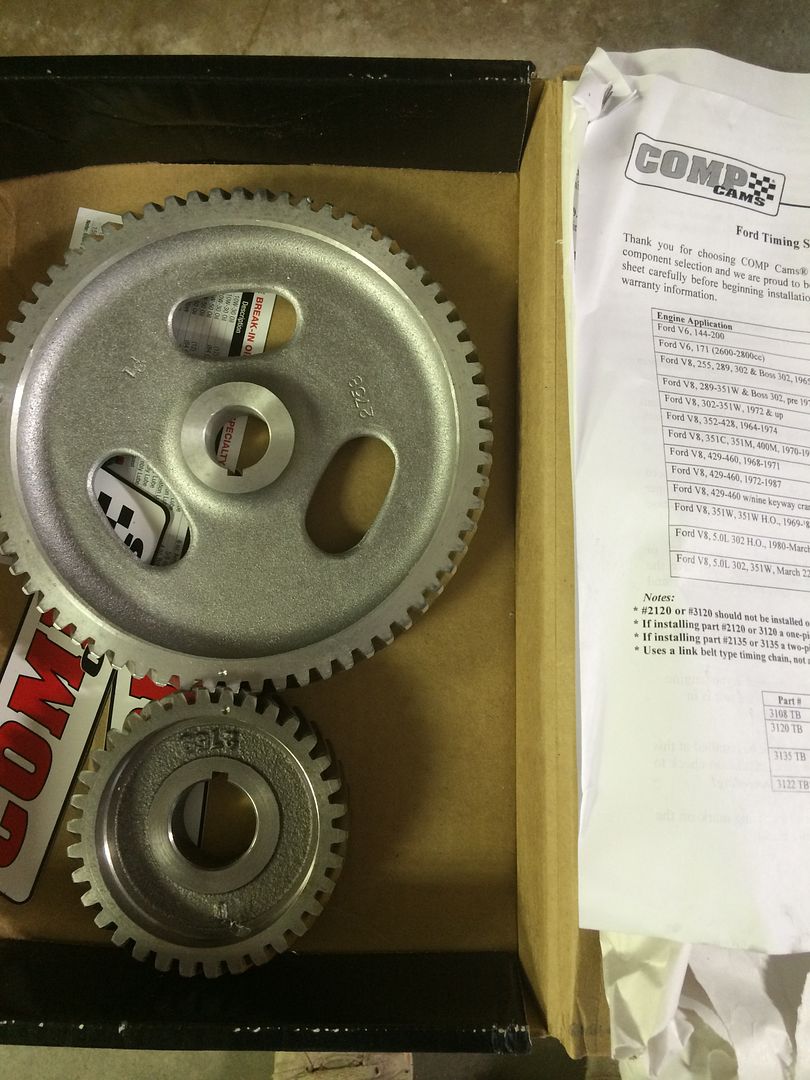

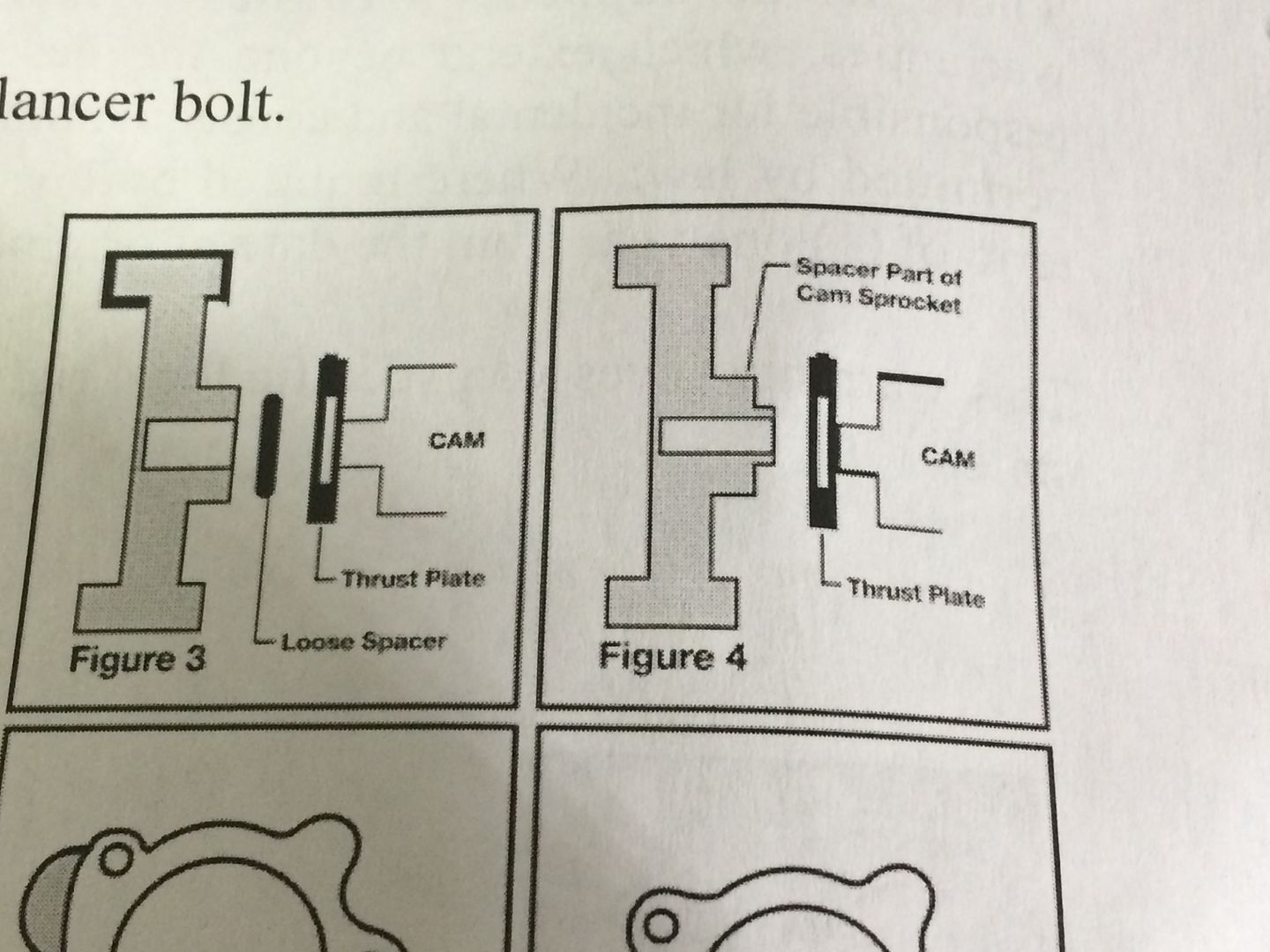

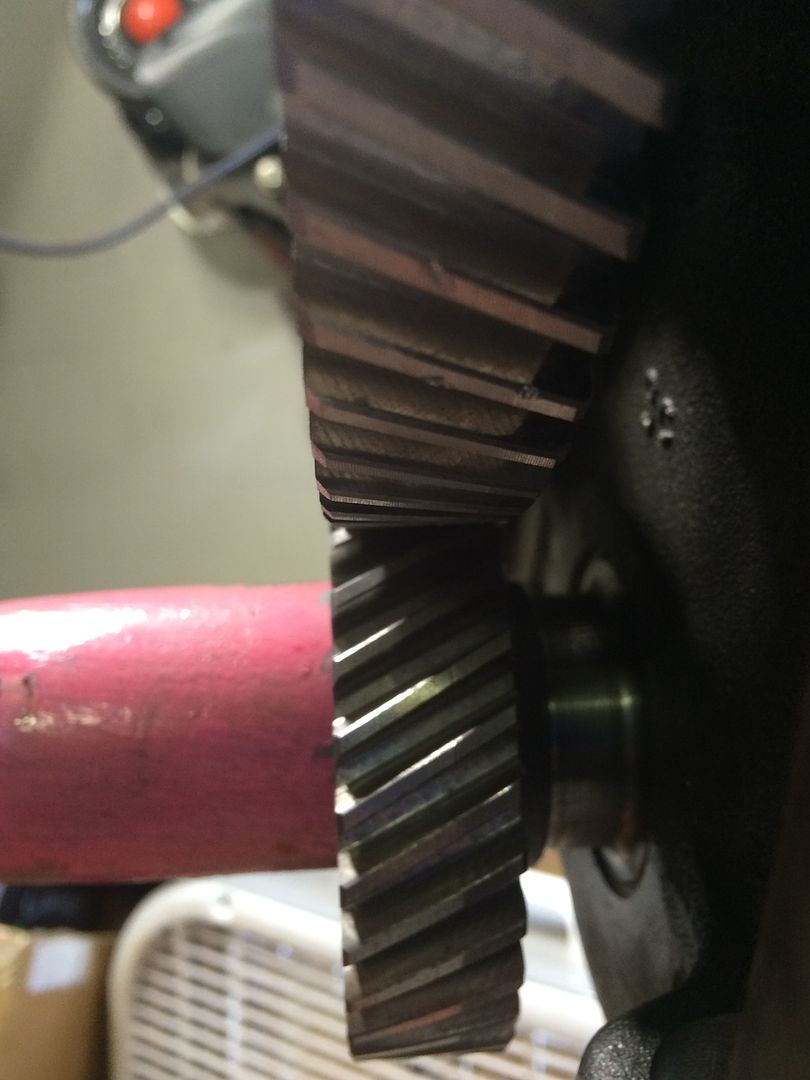

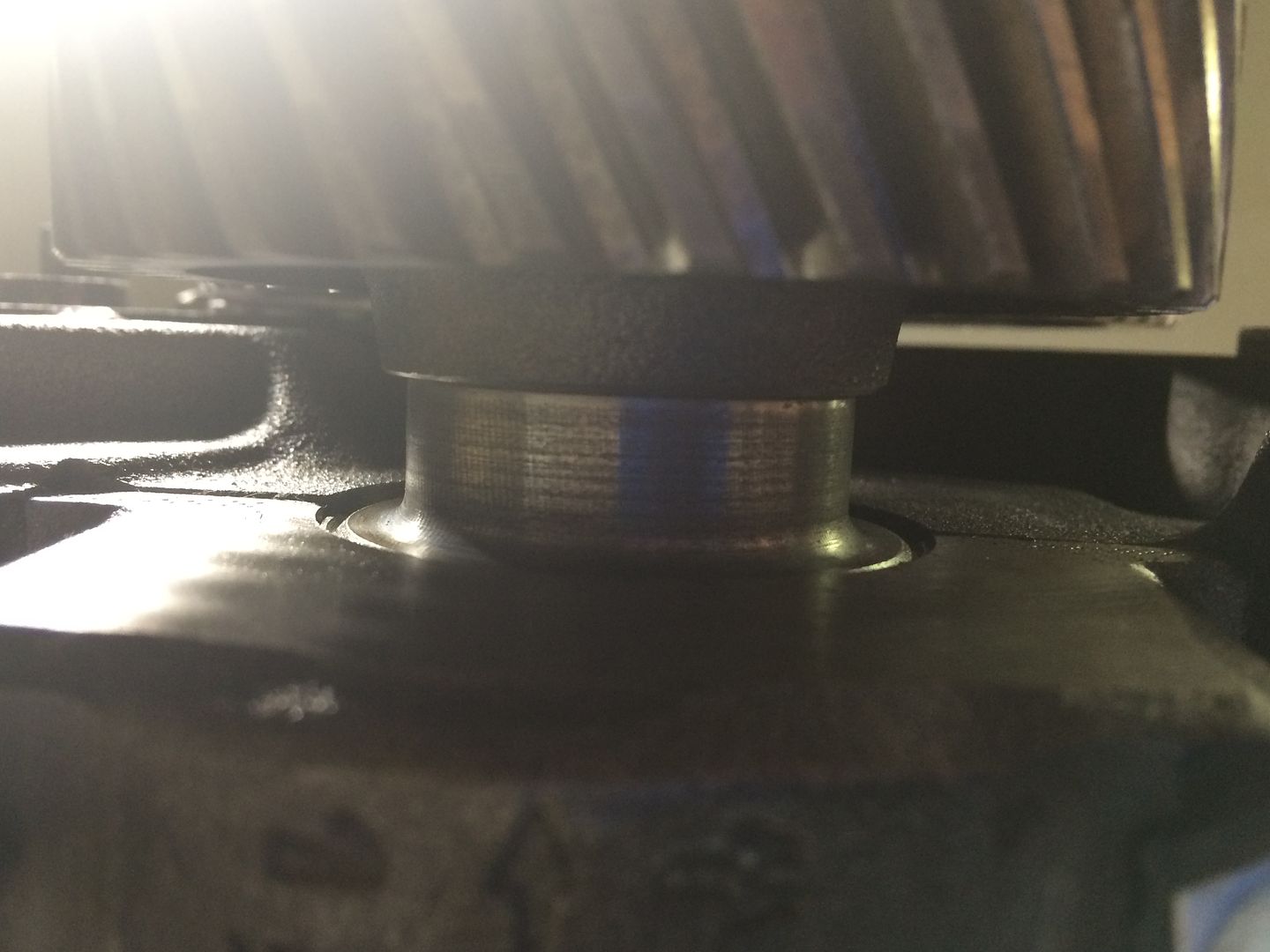

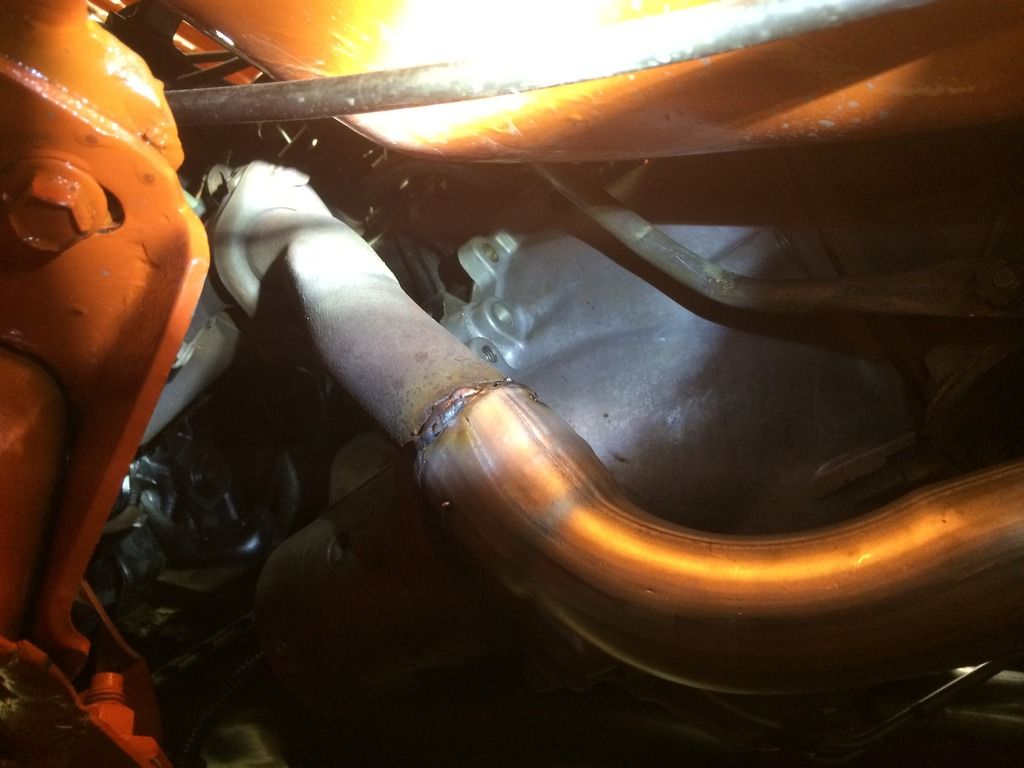

Reply With Quote ) and heating the sprocket in the oven got it on. I am not convinced it is on quite far enough although I could not, with two attempts get it on further. Everything is undamaged by sight. I am thinking when the crank pulley gets installed and torqued on it will slide the gear on if it needs to go more

) and heating the sprocket in the oven got it on. I am not convinced it is on quite far enough although I could not, with two attempts get it on further. Everything is undamaged by sight. I am thinking when the crank pulley gets installed and torqued on it will slide the gear on if it needs to go more

I'm thinking a piece of steel pipe or something that fits over the crank snout would work for even pressure.

I'm thinking a piece of steel pipe or something that fits over the crank snout would work for even pressure.

Connect With Us