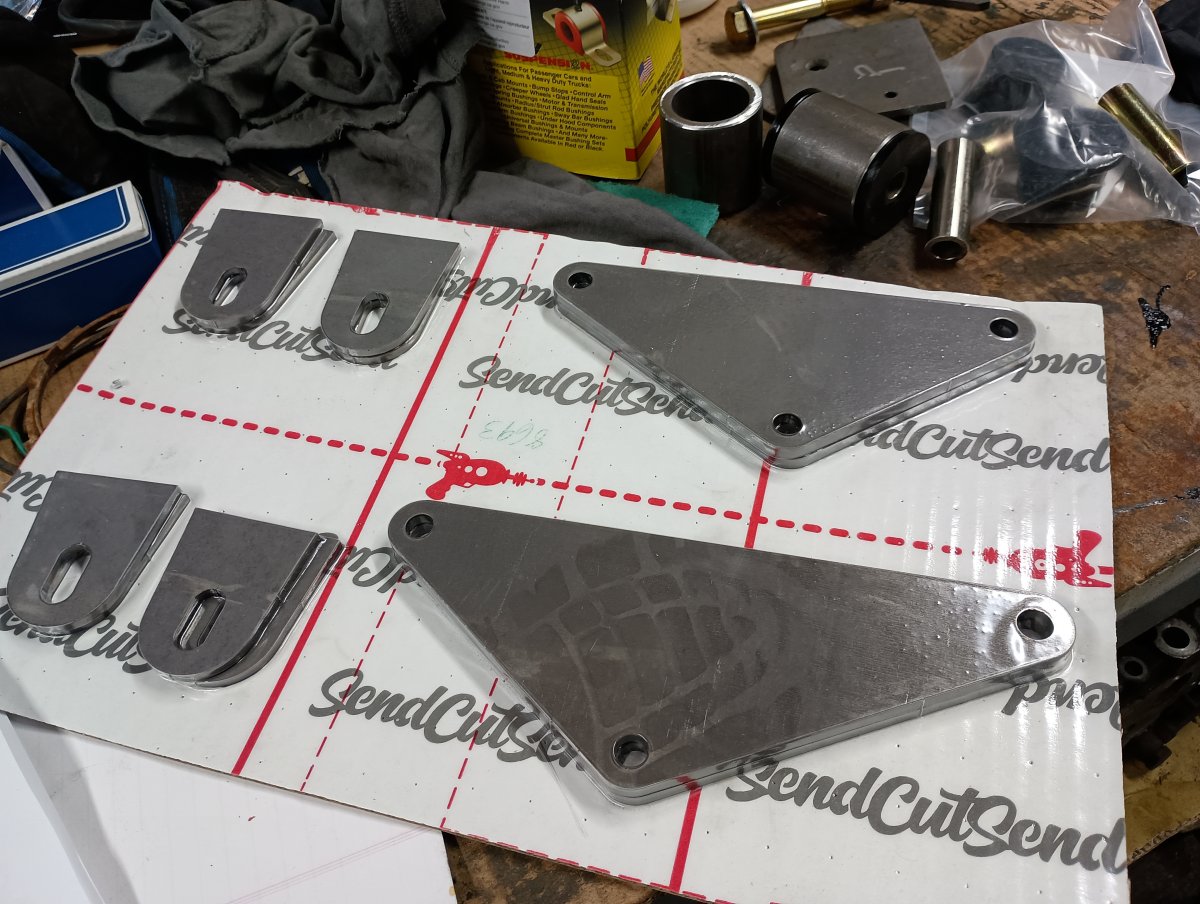

OK, the laser cut parts for my motor mounts showed up today. My old leftover stash from my time building mounts yielded the rest of what I'm going to need to get it all together.

I should have some time on Sunday to get a few things tacked up.

I also decided I'm going to use an SN-95 steering rack in this thing. I picked up a good, used rack from an '04 GT/Mach1, which should do nicely. I figured that since I was going to need to buy one of the MM steering shafts, I might as well upgrade the rack at the same time.

Reply With Quote

Reply With Quote

I got it covered for prepping them.

I got it covered for prepping them.

Connect With Us