I'm in the middle of a full brake refresh and am running into a few problems ordering and receiving the correct brake parts. I've only installed the calipers, pads and hoses at this point.

Thanks to FoxChassis who Posted on Stangnet:

'79-'93 Front Rotor Diameter:

9.31" - '80-'81

10.06" - '79 and '82-'86 (exc. '84-'86 SVO), '87-'93 w/ I4

10.84" - '87-'93 w/ V8 (exc. '93 Cobra "R")

10.91" - '84-'86 SVO

13" - '93 Cobra "R"

I think I have it all sorted now but need new bearings to go into my new front rotors with races already installed on Bendix PRT1175 with 9.3" OSD. Does anyone know the correct size for bearings for the 9.3" rotor? For SKF brand there are two different inners (BR 17 or 68149) and two different outers (A12 or LM12749 VP).

My M81 is a 2.3 Turbo Ghia and has build date of 07/80 and Vin 0F03A..... My Marti report lists the A as the NA 2.3L and below adds the Turbo to the feature list. LFAPS says my A in the vin indicates a non-turbo (W for Turbo) so parts become a crapshoot sometimes.

FWIW and to maybe help others with 1980/81 cars I have ordered the following based on 9" rear drums:

Rear

Drums: My part #D9ZC-1126-AA = 9"

wheel cylinders: with the 1/4" bleeder.

Rear center hose: # D9ZZ2282A or 4536829

Shoes: 1.75"

Shoe Spring kit: 1R3Z2225AA Motorcraft BRSK7246A needed for 9" brakes

Emergency brake kit: 1R3Z2V041BA pass and 1R3Z2V041AA driver I ordered Motorcraft BRAK2597 & BRAK2596 to fit the 9" brakes as the first generic set was for the 10" and had fitment issues last year. BTW Motorcraft box says Made in China- probably getting the same stamped crap and putting their name on it.

Front

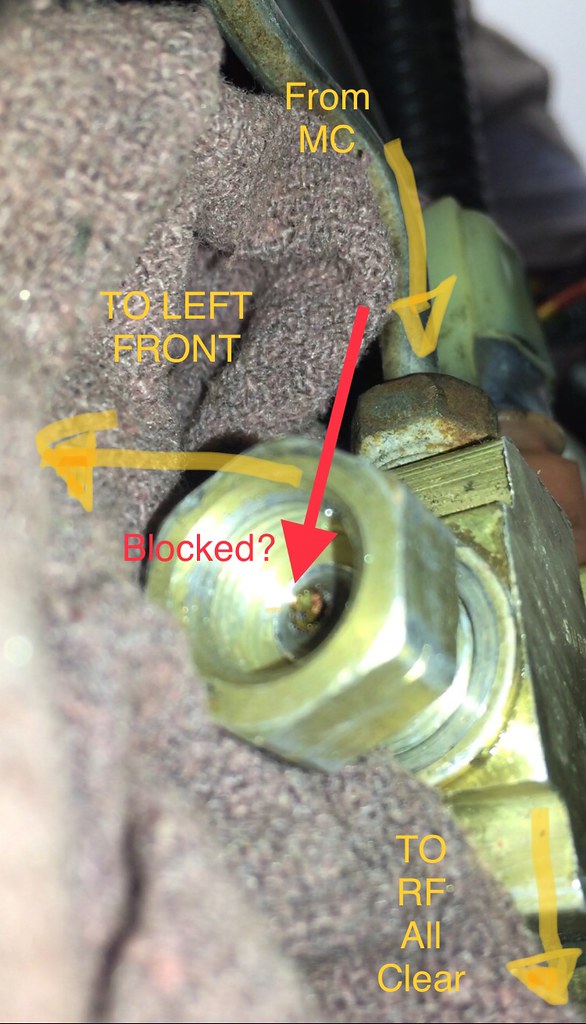

Master Cylinder: #D8BZ-2140-A for Power brakes, Bore: 7/8 In. or .0875 with 12mm and ½” -20 x 1, rear 7/16

Rotors: Ford# 9.3" OS DIA, I ordered Bendix PRT1175= Made in China

Calipers: Forgot Ford# will update= for 9" Rear Drum; M12 x 1.0 Inlet

Front Hoses: 4536854, D9BZ2078A, E0SZ2078A, E0ZZ2078A uses the M12mm x 1.0 thread on one end and standard 7/16 on the other.Length Overall (IN) 13.200. I ordered two BH98945 and the hoses are different (one is smooth and one has a bunch of small rounds/ridges like my OEM). Both installed fine.

Pads: #151M semi-metallic for 9.3" rotor

Stay healthy everyone!

Reply With Quote

Reply With Quote

Connect With Us