See

http://www.autospeed.com/cms/A_2370/article.html for details in metric. A tall deck, long rod 347W with Aussie ACL pistons should make a very easy 385 hp in EFI form with the right intake and exhaust.

MINIMUM FOR 347w BEST BANG FOR BUCK,

GT40P heads, with 1.9/1.64 valves and port work mainly on the exhaust side.

1.6:1 rockers

The 4% capacity increase should bring the compression up to 10.5:1

At very least, a Crane 2031, which is a 0.513/0.529, 276/282 duration.050 inch Lift: 214 int./220 exh. With 1:7 rockers and AFR 185 or 165 heads work better Piston to valve than the stock gt40's...piston to valve clearance is an issue with 1.7"1 rockers on a stock head.

Explorer manifold with 70mm tb, and a ford lightning 5.0 90mm MAF

balance the bottom end.

msd edis 4 ignition system

4 into 1 headers, twin 2.5" into single 3" exhaust

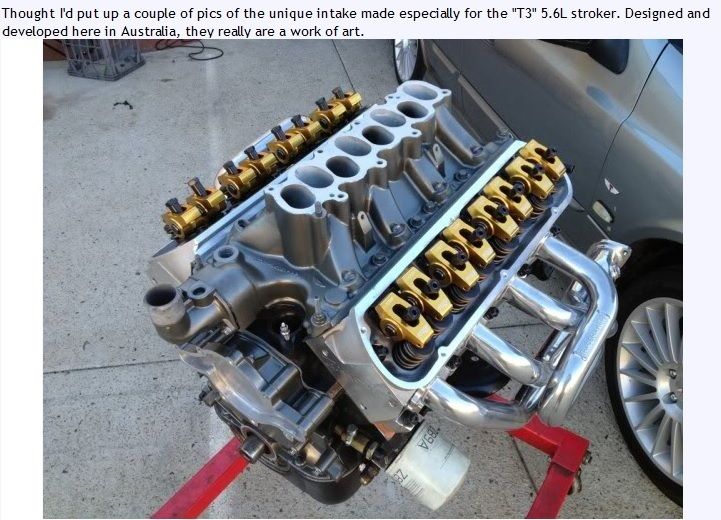

BEST 400 plus hp BUILD USNG JUNKED T3 ENGINE PARTS

− AFR 185cc Alloy heads- 60cc chambers, modified pedestal mounts

− Comp Cams XFI 5.0 Stroker hydraulic roller camshaft- 236/248 @ .050", 286/300 total, .579"/.579" lift

− Yella Terra 1.6 ratio adjustable Aluminum Roller Rockers

− Full ARP Head, rocker and main studs

− Full Felpro gasket set

− Isky adjustable guideplates

− Trend hardened chrom-moly pushrods

− PAC Beehive springs and Comp lightweight retainers

− Crane hydraulic lifters

− ACL Race series rings and bearings

− Rollmaster double row timing chain with nitrided gears

− Stock 302W roller block- factory bored .020" oversize, torque plate honed

− Stock T3 ACL Hypeurtectic pistons, dished and notched (9.7cc)

− 5.35 rods shotpeened with ARP bolts

− Aftermarket 3.40"nodular iron stroker crankshaft

− Stock T3 Intake manifold

− Stock T3 82mm throttle body

− Stock T3 laser cut main girdle

− Stock T3 oil pump and sump

− Stock T3 fuel pump and fuel lines

− Bosch 43Lb injectors

− 4 into 1 ceramic coated s/steel extractors, twin hi-flow 3" cats, twin 3" stainless steel all the way with X pipe, lukey Race mufflers and twin rear resonators

− AU Edit- extensively tuned by Simon from Xtreme Ford Tuning

− retuned BluePower chip

− MSD DIS-4 ignition system

− Walbro 255lph fuel pump

− MSD Blaster 4 tower coil packs

− MSD 8.5mm Super Conductor leads

− Launch control (2 stage RPM limit)

− Ford Lightning 90mm MAF

− 100mm intake assembly and shielded custom CAI with K&N filte

The Receivers and Managers of Automotive Components Limited (Receivers and Managers Appointed) (In Liquidation) (ACL) announced on Monday, 29 April 2013 that ACL is being offered for sale. The piston are around and going cheap.

site

http://catalog.acl.com.au

Reply With Quote

Reply With Quote

.jpg)

Connect With Us