I never have put any sealent on mine. I haven't check for bleed down but I doubt it, I am sure it is supposed to hold vacuum till it stops getting it.

I never have put any sealent on mine. I haven't check for bleed down but I doubt it, I am sure it is supposed to hold vacuum till it stops getting it.

1984.5 G.T.350 5.0 CFI AOD Convertible (TRX package, loaded)

K&N filter in a stock dual snorkel, GT40 heads, Edelbrock 3721 intake, MSD 8456 Dist., MSD 8227 coil

Comp cams XE254H, hypereutectic pistons

Hooker Super Comp Shorty Equal Length Headers, catted BBK H-pipe, full custom duals

Maximum Motorsports caster/camber plates and strut tower brace, 3.73 rear, dura grip (both Yukon)

Ford Performance Springs, Firehawk A/S 225/55r16 on LMR TRX r390 wheels (street)

Federal 595 rs-rr 245/40r17 and 255/40r17 on OE cobra r wheels (race)

AOD rebuilt with a 6 clutch direct drum, Koline steels stacked with 8 clutches, Kevlar band, superior shift kit, new torque converter. --Everything else stock and fully functional.

Strange...

1984.5 G.T.350 5.0 CFI AOD Convertible (TRX package, loaded)

K&N filter in a stock dual snorkel, GT40 heads, Edelbrock 3721 intake, MSD 8456 Dist., MSD 8227 coil

Comp cams XE254H, hypereutectic pistons

Hooker Super Comp Shorty Equal Length Headers, catted BBK H-pipe, full custom duals

Maximum Motorsports caster/camber plates and strut tower brace, 3.73 rear, dura grip (both Yukon)

Ford Performance Springs, Firehawk A/S 225/55r16 on LMR TRX r390 wheels (street)

Federal 595 rs-rr 245/40r17 and 255/40r17 on OE cobra r wheels (race)

AOD rebuilt with a 6 clutch direct drum, Koline steels stacked with 8 clutches, Kevlar band, superior shift kit, new torque converter. --Everything else stock and fully functional.

If the hand pressure rating has been overloaded on the scale, or the gage us defective, you might accidentially damage to rubber seal. Do check that by another means. Ive worked in two Burea Veritas testing laboratories. The danger with gages is that if they are in error or faulty, a user or operator might not pick it up.

About Respect https://www.youtube.com/watch?v=2bk9WG8KWW0

X's Album http://vb.foureyedpride.com/album.php?albumid=2922

Oz JPS Stang http://www.nzmustang.com/Images/Hist...cecars/jps.htm

4V (A)US Race V8's https://www.youtube.com/watch?v=Tqk18A-ibjA

ITZOLD 81 Fox http://vb.foureyedpride.com/showthre...-fun-and-games

6V i6's @ http://www.xecltd.info/?rd=10 ; AWD i6's @ http://www.apetracing.co.nz/

113 mph 84 5.0 at Amaroo https://www.youtube.com/watch?v=iTezv3Pzdls&t=8s

Techno KCM Loop Out: Severed Heads 1m³ Angels 1985 https://youtu.be/Wll6G1KpLqQ

Future Shock https://youtu.be/rDKGkWU0lWQ

I did connect a vacuum gauge at the light blue vacuum line when the vac kicked in and it measured at 18 so its already where you told me to try to set it.

I can see visually that its the choke that's not pulling the kickdown step plate all the way open. it cold idles at 2100 RPM so the cold setting is working but it doesn't kick down to low idle until I drive the car for at least 20 minutes and shut it of and restart once or twice.

My new Motorcraft choke should be here by tomorrow and my new choke kick down diaphragm should be here by Monday. I think the choke I have in there now is Standard. I'm getting a genuine Motorcraft so hopefully I can resolve all of this.

Because I tried adjusting the cold idle screw it affected the voltage of the TPS, and last night the car was sputtering when driving at cruising speed, so now I have to go through all the settings,

cold idle speed

set TPS voltage

set choke cold idle

verify or adjust choke fully warm position.

Is there a way to bench test a choke to make sure it functions? I was thinking of leaving the choke off the CFI just lying on a shop rag, connecting the voltage wire and grounding it with an alligator clip to the CFI, then run the engine to see how much travel the choke thermostat spring has. Maybe clean the inside of the choke housing on the CFI with carb cleaner then lubricate the step plat mechanism with graphite?

Update on this situation. My new parts arrived today so I got into it this afternoon. I discovered a few interesting things.

First I took apart the choke pull down assembly. I found the lever that pulls the cam down was pretty worn and had score mark from riding the same posistion for years so I took it out and wire wheeled it clean and lightly scuffed the trigger part to smooth over the gouge.

Next I took a look at the back end of the choke pull down assembly that faces the firewall. Easy to overlook, so I put my cell phone in selfie mode to take a pic of it. It was filthy, I wasn't in the mood to pull the CFI off the intake so I just kept rubbing it with sandpaper until it felt smooth to my fingers.

Then I disassembled the components of the choke thermostat. I found the idle cam to be rusty and the mechanism the choke rides on to be gunked up so I cleaned them both.

I put it all back together after cleaning and applying a thing smear of never seize.

Then I set the position of the pull down lever. Had to take it apart 3 times until I got it to the correct position to pull down the cam one notch. I tested with vacuum pump and tested for vacuum integrity and it now holds vacuum.

Lastly I bench tested both the old and the new choke stoves with an old car battery, two wires with alligator clips. As I suspected, the old choke stove is dead. No movement of the coil, but the new one responds to battery voltage immediately. It got dark here at 5 PM so I stopped but I'm going to put the new choke on tomorrow and I am 100% certain that was the cause of my idle not dropping down when the car warmed up. Yes there was voltage getting to the choke thermostat, but it wasn't responding to that voltage.

As I said, I read in another forum that 12 volts over the long term is bad for stock Ford choke thermostats. they were built to take 7 volts from the stator. And since my mechanic jumped the choke thermostat to the ignition coil when he updated my charging system to 3G around 4 years back. I can only assume over time it was bad for the choke thermostat.

Last edited by fgross2006; 02-01-2020 at 06:41 PM.

Sounds like you got it! What led you to do the 3g? I haven't done it yet... Was it need for juice or worries about fire?

1984.5 G.T.350 5.0 CFI AOD Convertible (TRX package, loaded)

K&N filter in a stock dual snorkel, GT40 heads, Edelbrock 3721 intake, MSD 8456 Dist., MSD 8227 coil

Comp cams XE254H, hypereutectic pistons

Hooker Super Comp Shorty Equal Length Headers, catted BBK H-pipe, full custom duals

Maximum Motorsports caster/camber plates and strut tower brace, 3.73 rear, dura grip (both Yukon)

Ford Performance Springs, Firehawk A/S 225/55r16 on LMR TRX r390 wheels (street)

Federal 595 rs-rr 245/40r17 and 255/40r17 on OE cobra r wheels (race)

AOD rebuilt with a 6 clutch direct drum, Koline steels stacked with 8 clutches, Kevlar band, superior shift kit, new torque converter. --Everything else stock and fully functional.

Nice work fgross....your dedication has nailed the problem. The CFi is a faithfull old girl at that!

About Respect https://www.youtube.com/watch?v=2bk9WG8KWW0

X's Album http://vb.foureyedpride.com/album.php?albumid=2922

Oz JPS Stang http://www.nzmustang.com/Images/Hist...cecars/jps.htm

4V (A)US Race V8's https://www.youtube.com/watch?v=Tqk18A-ibjA

ITZOLD 81 Fox http://vb.foureyedpride.com/showthre...-fun-and-games

6V i6's @ http://www.xecltd.info/?rd=10 ; AWD i6's @ http://www.apetracing.co.nz/

113 mph 84 5.0 at Amaroo https://www.youtube.com/watch?v=iTezv3Pzdls&t=8s

Techno KCM Loop Out: Severed Heads 1m³ Angels 1985 https://youtu.be/Wll6G1KpLqQ

Future Shock https://youtu.be/rDKGkWU0lWQ

That was the first major overhaul I did after I got this car back in 2014. That first summer I drove this car I kept finding a dead battery after running a few errands. The more errands, the more times I would shut it down and restart, the battery got weaker. Until by the 3rd errand the crank would die.

I replaced the alternator twice, replaced the voltage regulator twice with genuine motorcraft, replaced the wiring, cleaned all the connections yet The alternator tested at 14 volts but I ended up with a car needing a jump every day. It would have a strong crank first thing in the morning. The I'd run to 7-11 for coffee, come out and the crank would be weaker. Say an hour later I'd run to Home Depot, come out the crank would be weak enough to die but at the last second the engine would turn over. Later I'd make a 3rd stop and that's when I'd find the crank so weak it would just die.

I got tired of playing, tired of calling someone to bring jumper cables. I bought the 3G upgrade from LMR and I have not had a charging problem since.

Since I messed with the cold idle screw position last week I messed up the setting and the TPS voltage. I am going to go over every setting soup to nuts.

I found this link to a PDF that explains, with diagrams, the procedures for setting the idle on various Ford engines. Since I cant attach a pdf, I'm linking direct to it.

https://www.google.com/url?sa=t&rct=...VxxDcsBNVKkDaE

At the top of page one the different engine types are hyperlinked. Click on the one for CFI 5.0 engine and it brings to page 5 of the PDF.

The procedure for setting the cold idle is as follows,

To adjust idle speed:

1. Connect a tachometer to the engine. Apply the parking brake and disconnect and plug the

vacuum hose for the vacuum-operated parking brake. Then start the engine and warm it

to normal operating temperature.

2. Ensure that vacuum is not present at the vacuum-operated throttle modulator (VOTM). If

vacuum is present, verify that the engine is fully warm and that all air conditioning and

ventilation controls are switched off.

3. Adjust the fast idle speed as follows:

a. Turn the engine off.

b. Disconnect and plug the vacuum hose at the EGR valve.

c. Disconnect and plug the evaporative purge hose at the throttle body spacer.

d. Place the transmission in park and restart the engine.

e. Place the fast-idle cam on the highest step (Figure F050-5).

f. Start the engine and turn the fast-idle adjusting screw to set the engine speed to the

rpm listed on the VECI decal.

I got this one from another website, similar procedure, written differently;

Fast Idle Reset

1. Place the transmission in Neutral or Park

2. Start the engine and bring the engine to normal operating temperature

3. Disconnect the vacuum hose at the EGR Valve and plug it. Disconnect and plug the canister purge vacuum line

4. Disconnect and plug the vacuum hose at the fast idle pull down motor. Turn the ignition off

5. Set the fast idle lever on the high step of the fast idle cam

6. With a tachometer, check and adjust the fast idle rpm between 20 and 60 seconds after restarting the engine. If this time limit is exceeded repeat steps 4 and 5

7. Remove the plug from the EGR hose and reconnect it. Remove the plug from the fast idle pull down motor vacuum hose and reconnect it

8. Reconnect the canister purge line

So whet I get from these is that I should be setting the cold idle AFTER bringing the engine to full operating temperature? AND I should be plugging the EGR vacuum line, the canister purge valve line (Before ?) the canister purge valve. According to the second list I should plug the choke cam pull down hose and the first list says to plug the plug the vacuum hose for the vacuum-operated parking brake. What does that even mean? Vacuum operated parking brake? Vacuum cant exist when the engine is off and parking brakes are applied when cars are not running so WTH? And if I'm supposed to plug the choke pull down vacuum, why not also plug the VOTM Dashpot vacuum line? They are both fed from the same line and solenoid?

It says to attach a tachometer to check RPM's. I have always relied on the tach on the dash. I dont own an external tach, dont feel like buying one for a once in a blue moon procedure. Is the dash tach accurate enough?

I just want to be clear on this when I start adjusting the cold idle. I know after I get it set at 2100 RPM I will have to reset the TPS voltage since turning the cold idle screw alters the TPS position. Then I will have to reset the curb idle.

I set the cold idle on mine to 1600ish. I let the car do the rest. I have the correct cold idle instructions somewhere but I found them if no value. Couple hours of driving and my car figures it out on its own. 550 rpm warm in gear. 800 in park warm. 1600 cold start. 1100ish after the kickdown. Then down to 800 ish in drive until fully warm.

1984.5 G.T.350 5.0 CFI AOD Convertible (TRX package, loaded)

K&N filter in a stock dual snorkel, GT40 heads, Edelbrock 3721 intake, MSD 8456 Dist., MSD 8227 coil

Comp cams XE254H, hypereutectic pistons

Hooker Super Comp Shorty Equal Length Headers, catted BBK H-pipe, full custom duals

Maximum Motorsports caster/camber plates and strut tower brace, 3.73 rear, dura grip (both Yukon)

Ford Performance Springs, Firehawk A/S 225/55r16 on LMR TRX r390 wheels (street)

Federal 595 rs-rr 245/40r17 and 255/40r17 on OE cobra r wheels (race)

AOD rebuilt with a 6 clutch direct drum, Koline steels stacked with 8 clutches, Kevlar band, superior shift kit, new torque converter. --Everything else stock and fully functional.

I put it all together today but first I made a quick video of me testing the choke thermostats,

After I put the new choke thermostat in and ran the car i could see immediately that it was able to kick down. So after that i set the cold idle to 2200 RPM as it says in the Ford instructions. Thermostat pull down triggered it to about 1800 rpm, then thumping the accelerator brought it down the rest of the way. I reset TPS to .97 volts. I found the bolt hole closer to the firewall is stripped but with enough torque on the front hole its holding the TPS voltage steady. this summer when its nice out I will have to pull the CFI and tap it out. Fix with a heli coil I suppose.

I finished by resetting curb idle, after a few tries i got it to 550 rpm in drive. I am remembering when I first got the car there was some serious issues with getting it to idle correct and my mechanic determined the choke thermostat was bad. Im surprised the motorcraft one I put in failed after 4 years but then again the 12 volt connection may have aged it too soon.

Great. I never could stand it running at 2200 cold though...

1984.5 G.T.350 5.0 CFI AOD Convertible (TRX package, loaded)

K&N filter in a stock dual snorkel, GT40 heads, Edelbrock 3721 intake, MSD 8456 Dist., MSD 8227 coil

Comp cams XE254H, hypereutectic pistons

Hooker Super Comp Shorty Equal Length Headers, catted BBK H-pipe, full custom duals

Maximum Motorsports caster/camber plates and strut tower brace, 3.73 rear, dura grip (both Yukon)

Ford Performance Springs, Firehawk A/S 225/55r16 on LMR TRX r390 wheels (street)

Federal 595 rs-rr 245/40r17 and 255/40r17 on OE cobra r wheels (race)

AOD rebuilt with a 6 clutch direct drum, Koline steels stacked with 8 clutches, Kevlar band, superior shift kit, new torque converter. --Everything else stock and fully functional.

When i ran electric chokes on my carbs, once had a shorted choke melt some wires in the alt to regulator harness.

Kept draining battery. Battery would not charge correctly or even at all for several days.

Took it to dealer. Requested full under hood electrical check. They found the burnt choke. Not the melted wires.

Next day, almost made it to work. Dead. Had some time. Something told me to check deep in the harness. Bingo.

Repaired the wires, added a 5a inline fuse to the choke wire from the alt.

Never happened again.

Soon after, disabled the choke. Engine really did/does not start or run cold much different without it (2.3T).

Was and is piece of mind choke was/is always wide open.

Now have installed a manual Holley choke on the new carb just in case.

Set a 1/4-1/2 closed starting a winter cold engine, then i keep engine alive with pedal till it idles on its own and revs smoothly.

Couple minutes warm up, good to go. I open choke as needed when engine starts bogging- saying enough already..

Connecting choke to coil is a no-no. Direct to 12v or any unfused power source is too.

If using 12v, connect to key on circuit only. Choke should only be powered when engine is running.

Read certain design 12v chokes are cooled inside by engine vac.

I have to ask, is the VOTM, aka, the dashpot supposed to hold vacuum? I replaced mine with a Motorcraft NOS dashpot about 4 years back. I noticed today when I apply vacuum with hand held pump it bleeds right down, but a constant vacuum pull will enable the dashpot to function.

I'm not sure if its supposed to do that. I saw one on Ebay last month, I'm kicking myself for not grabbing it up. Since the vacuum controlled VOTM are hard to find I was wondering if there's a company, service or website that can rebuild/refurbish old ones?

I can look in the garage and see if my extra dashpot is still together. Since I put my strut bar in it is a pain to pull the whole air cleaner assembly off. That VOTM just 'kicks' the throttle for you so I guess it could do its job without holding vacuum for long. Since it only receives vacuum if it needs to kick down or if all hell is breaking loose (at least that is what I have noticed) it probably doesn't matter much. Funny thing is when it 'feels the need' to bump the throttle, in each time I have noticed, it was when the engine was so far gone no amount of throttle modulation was going to rescue the idle in it (bad PIP).

1984.5 G.T.350 5.0 CFI AOD Convertible (TRX package, loaded)

K&N filter in a stock dual snorkel, GT40 heads, Edelbrock 3721 intake, MSD 8456 Dist., MSD 8227 coil

Comp cams XE254H, hypereutectic pistons

Hooker Super Comp Shorty Equal Length Headers, catted BBK H-pipe, full custom duals

Maximum Motorsports caster/camber plates and strut tower brace, 3.73 rear, dura grip (both Yukon)

Ford Performance Springs, Firehawk A/S 225/55r16 on LMR TRX r390 wheels (street)

Federal 595 rs-rr 245/40r17 and 255/40r17 on OE cobra r wheels (race)

AOD rebuilt with a 6 clutch direct drum, Koline steels stacked with 8 clutches, Kevlar band, superior shift kit, new torque converter. --Everything else stock and fully functional.

Strange thing is gr79, on the CFI there is no actual choke. the damned thing still has the choke heater to just crack the throttle during warm up. The computer creates a rich mixture on the injectors until the engine is at operating temp.

1984.5 G.T.350 5.0 CFI AOD Convertible (TRX package, loaded)

K&N filter in a stock dual snorkel, GT40 heads, Edelbrock 3721 intake, MSD 8456 Dist., MSD 8227 coil

Comp cams XE254H, hypereutectic pistons

Hooker Super Comp Shorty Equal Length Headers, catted BBK H-pipe, full custom duals

Maximum Motorsports caster/camber plates and strut tower brace, 3.73 rear, dura grip (both Yukon)

Ford Performance Springs, Firehawk A/S 225/55r16 on LMR TRX r390 wheels (street)

Federal 595 rs-rr 245/40r17 and 255/40r17 on OE cobra r wheels (race)

AOD rebuilt with a 6 clutch direct drum, Koline steels stacked with 8 clutches, Kevlar band, superior shift kit, new torque converter. --Everything else stock and fully functional.

I wanna ask, should the cold idle be set when the car is cold? makes sense doesn't it?

I followed Ford's instructions to warm the car up first, then set the high cam then set the idle to 2200 RPM. I had it all set yesterday but the true test is the first cold morning start after setting it. Today I start the car and it goes to 1100 RPM on the high cam. It kicks down to 800 RPM on the second step, then when I thumped the gas pedal it drips to maybe 350 RPM in park. In drive the engine cant sustain itself.

I remember in the past i always set the cold idle on a cold morning. The lousy thing is that I'll have to wait till tomorrow to try to set it. I know once you start the car and even partially warm it up the opportunity for tweaking the setting is gone.

Yeah, I set mine when it is cold. Was that 350 when it was full warm? Just looked in the garage and I only have the votm on the car.

1984.5 G.T.350 5.0 CFI AOD Convertible (TRX package, loaded)

K&N filter in a stock dual snorkel, GT40 heads, Edelbrock 3721 intake, MSD 8456 Dist., MSD 8227 coil

Comp cams XE254H, hypereutectic pistons

Hooker Super Comp Shorty Equal Length Headers, catted BBK H-pipe, full custom duals

Maximum Motorsports caster/camber plates and strut tower brace, 3.73 rear, dura grip (both Yukon)

Ford Performance Springs, Firehawk A/S 225/55r16 on LMR TRX r390 wheels (street)

Federal 595 rs-rr 245/40r17 and 255/40r17 on OE cobra r wheels (race)

AOD rebuilt with a 6 clutch direct drum, Koline steels stacked with 8 clutches, Kevlar band, superior shift kit, new torque converter. --Everything else stock and fully functional.

It was around 250 -350 after kick down past 3rd cam, but I didn't let the car warm up past that. I shut it off because it was not set right and I didn't want it to reach operating temp at that RPM. I need to try again either later in the afternoon or tomorrow morning.

I don't understand why Ford instructs to bring the car to full operating temp and THEN set the COLD idle. it makes no sense.

Now I have to play with the cold idle screw which means playing with the TPS voltage again, and re setting curb idle again. A shame, yesterday it was running great.

I found this VOTM on ebay. It's identical to mine but the numbers dont match up.

This is the number on mine, E2VE-9E957-AB

This one is listed on ebay and the auto compatibility chart does not list any Mustangs. Seems to be for Econoline vans. E2AE-9E957-BB

But is it the same? Can it function on a Mustang?

I'm still wondering if these dashpots can be refurbished with new internal diaphragm.

Fords 1984 EECIV M- code 5.0 HO Fuel injection V8 used a TOTALLY different system to Passenger and Truck 2 bbls or 4bbls.

Not the same as the carb Holley or Motorcrafts, but I'm not saying no, E2VE-9E957-AB to E2AE-9E957-BB, but that its VERY BLQQDY UNLIKELY!

And The 1984-1985 CFi is different from the EECIII 1980 TO 1984 5.0 SO Fuel Injection V8's and V6's,

FoMoCo customized each install.

The generic call names for Fords Emissions and Engine control systems in the VECI are similar.

In Ford speak, Vehicle Emission Control Information = (VECI)

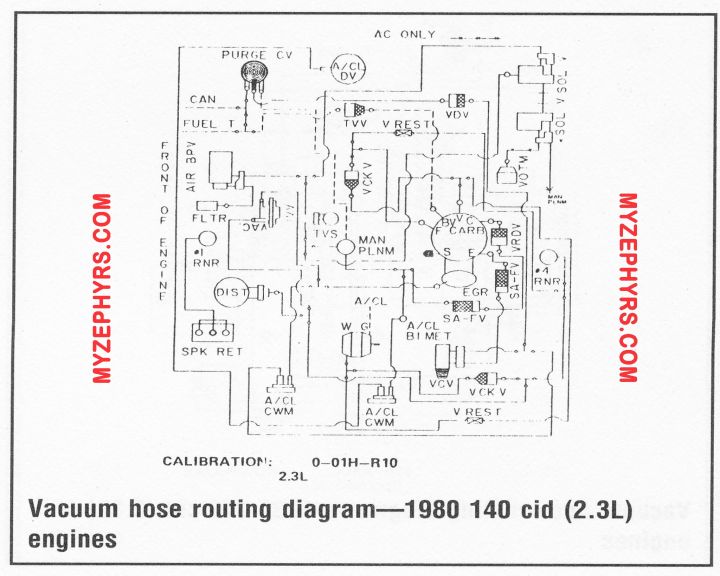

The Authorized Cannon is this one from circa 1979

http://myzephyrs.com/vac_part_name.htm

For instance, the 2-bbl 2.3 Turbo Mustang from 79-82 used a VOTM,

On some, it was similar looking, but a Throttle Kicker exists for AC installs on trucks.

Throttle Solenoid Positioner (3.3 B code for 1982, X code for 1983).

Essentially, through these Windsor, Essex, Cleveland, Lima, ProCo, and CVHH projects, Ford USA and Canada simply dialed in on what was important from there parts inventory, and decided that

the idle,

mixture,

ignition and

carb systems were best kept Dead Detroit simple,

The festooning of the other 103 or whatever other bits were just to keep everything serviceable with a shop gas meter, a rolling road, and a scope or multi meter.

2 and 4bbl Carb Fox V8s didn't have the VOTM, they had the Idle Stop Solenoid. Listed in the EVTM , but never on the VECI for carb 5.0s'

Last edited by xctasy; 02-03-2020 at 06:27 PM.

About Respect https://www.youtube.com/watch?v=2bk9WG8KWW0

X's Album http://vb.foureyedpride.com/album.php?albumid=2922

Oz JPS Stang http://www.nzmustang.com/Images/Hist...cecars/jps.htm

4V (A)US Race V8's https://www.youtube.com/watch?v=Tqk18A-ibjA

ITZOLD 81 Fox http://vb.foureyedpride.com/showthre...-fun-and-games

6V i6's @ http://www.xecltd.info/?rd=10 ; AWD i6's @ http://www.apetracing.co.nz/

113 mph 84 5.0 at Amaroo https://www.youtube.com/watch?v=iTezv3Pzdls&t=8s

Techno KCM Loop Out: Severed Heads 1m³ Angels 1985 https://youtu.be/Wll6G1KpLqQ

Future Shock https://youtu.be/rDKGkWU0lWQ

Ah yes CFI. Duh.. was thinking it had a choke flap too. Of course that is not the way TBI , FI, does cold start enrichment.

Geez i dont even do super bowl partying.

Was not aware of the 'throttle cracking with choke heater' assy. Never knew such existed.

Unfortunately never had my nice 85 LTD LX long enough to dig into anything under the hood. Car was only 2y old, 50K.

Except for changing that ps rear spark plug plus putting up with the warm engine spark ping and low idle stalling issues.

Having kept the 85 Ford shop manual set, read up about the Cold Engine Speed Control, the choke spring's 7.3v from alt stator, etc.

May never play with those things, but found related knowledge in other systems can help as to how another works. Another angle.

Tinkering is a valuable learning experience as to what does what for repair or fine tune in addition to all other known procedures.

Well done! i was wrong, you have found it!

OEM Ford E2AE-9E957-BB is for the the VV 7200 Variable Venturi Carburetor 2-BBL Idle Dashpot on 5.0 and 5.8s.

E vans till 1985, and then Panther full size sedans from 1986-1987.

The revision number might be different, but....OE#E2AE-9E957BA/BB is the list from 1983 to 1987, so I'd try it!.

Hence Fords EEE department re-purposed VV 7200 for the 1984-1/2 to 1985 HO 5.0 Central Fuel Injection.

CFYI.

In this post, the OP had a 4bbl Mustang. It is the CFi VOTM, the 4-BBL had a dashpot solepot kicker, no VOTM.

E3AE-9S520-BA is found on the 1983 2150 2-bbls as well, its an Idle Stop solenoid, not a VOTM.

E0AE-9E957-CA Carburetor VOTM 80-82 Ford 4.2/5.0L 2-BBL 2150 or VV 7200 or CFi

Last edited by xctasy; 02-03-2020 at 06:28 PM.

About Respect https://www.youtube.com/watch?v=2bk9WG8KWW0

X's Album http://vb.foureyedpride.com/album.php?albumid=2922

Oz JPS Stang http://www.nzmustang.com/Images/Hist...cecars/jps.htm

4V (A)US Race V8's https://www.youtube.com/watch?v=Tqk18A-ibjA

ITZOLD 81 Fox http://vb.foureyedpride.com/showthre...-fun-and-games

6V i6's @ http://www.xecltd.info/?rd=10 ; AWD i6's @ http://www.apetracing.co.nz/

113 mph 84 5.0 at Amaroo https://www.youtube.com/watch?v=iTezv3Pzdls&t=8s

Techno KCM Loop Out: Severed Heads 1m³ Angels 1985 https://youtu.be/Wll6G1KpLqQ

Future Shock https://youtu.be/rDKGkWU0lWQ

You shouldn't have to be mucking with the tps voltage at all, it should zero itself at startup, tps problems come from jumping voltage and limited range, not initial voltage.

1984.5 G.T.350 5.0 CFI AOD Convertible (TRX package, loaded)

K&N filter in a stock dual snorkel, GT40 heads, Edelbrock 3721 intake, MSD 8456 Dist., MSD 8227 coil

Comp cams XE254H, hypereutectic pistons

Hooker Super Comp Shorty Equal Length Headers, catted BBK H-pipe, full custom duals

Maximum Motorsports caster/camber plates and strut tower brace, 3.73 rear, dura grip (both Yukon)

Ford Performance Springs, Firehawk A/S 225/55r16 on LMR TRX r390 wheels (street)

Federal 595 rs-rr 245/40r17 and 255/40r17 on OE cobra r wheels (race)

AOD rebuilt with a 6 clutch direct drum, Koline steels stacked with 8 clutches, Kevlar band, superior shift kit, new torque converter. --Everything else stock and fully functional.

Connect With Us