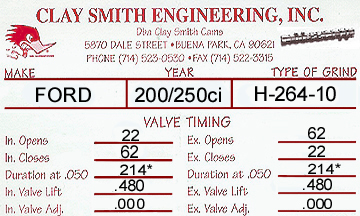

Duration advertised 264-264 (I never pay much attention to this, too tricky to measure and too little meaning)

Duration at .050" lobe 214-214 (this is the key measurement, when the dial indicator is .050" off the base circle)

Lobe separation 110 ICL=Intake CenterLine=110 ECL=ExhaustCenterLine=110 so Advance=0

(The CI site says their cams are straight up, ie 0 advance, but they recommend installing them at 4 advance)

https://fordsix.com/archive/www.clas...CamDegree.html

With the dial indicator you should measure, at .050" lobe lift

IO -3 (3 AFTER top center)

Max intake lift (imprecise but a good sanity check) at 110 ATC, same as 70 BBC

IC 37 (37 after bottom center)

(Duration = 180 -3 +37 = 214)

EO 37 (37 before bottom center)

Max exhaust lift (imprecise but a good sanity check) at 110 BTC, same as 70 ABC

EC -3 (3 BEFORE top center)

(Duration = 180 +37 -3 = 214)

Well thats what your cam card should have said, hope this helps.

If you then install it with 4 degrees crank advance (sometimes a good idea, depends on the rest of the engine and car though)

Then re-check it and you should get

IO +1 (1 BEFORE top center)

Max intake lift (imprecise but a good sanity check) at 106 ATC, same as 74 BBC

IC 33 (33 after bottom center)

(Duration = 180 +1 +33 = 214)

EO 41 (41 before bottom center)

Max exhaust lift (imprecise but a good sanity check) at 114 BTC, same as 66 ABC

EC -7 (7 BEFORE top center)

(Duration = 180 +41 -7 = 214)

Reply With Quote

Reply With Quote

I guess I'll need to take a look at the timing set I bought.

I guess I'll need to take a look at the timing set I bought.

Connect With Us