Hello, all:

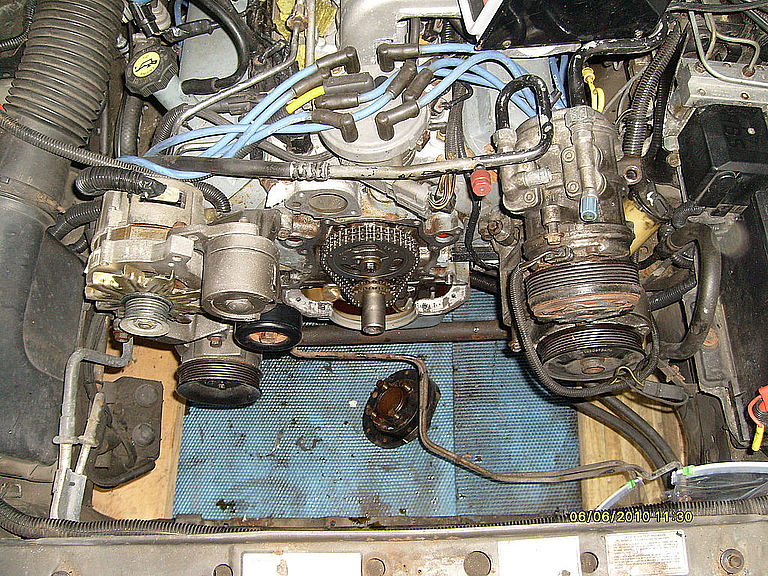

Let's see if I have this correct. Finally fixed the broken water pump bolt problem and now ready for the rest of the install- 86GT.

I only install the timing cover hand tight, then install the harmonic balancer so as to correctly line up the cover and gasket ensuring no leaks. Then torque the timing cover bolts. The torque on the balancer bolt is steep according to Ford. I think around 80 to 90 foot pounds. Impact or no?

Thanks.

Reply With Quote

Reply With Quote

Connect With Us