Te tf manual rack rebuild, other racks will be similar to build.

This is a guide only.

The te tf manual racks share the same bearings, bush, preload bush, boots and I think rackends as early commodores vb vc pretty sure the vh vk are also the same but not 100% sure, vl is definitely different. This also applies to the p/s racks.

Replaceable parts

The rack bush

Preload bush <<< I reused the original , they are cheep but the place I get my steering, trans and diff parts didn't have one in stock.

Top seal<<< i reused the original

Bearings <<< I reused the original, depending on condition

Boots

Rackends <<< I reused original, depending on condition

The rack I had to rebuild looked to be poor condition but one it was apart was really good inside .

Tools needed

Side cutters

Drill and drill bit 5/32

Stilsons and it big multigrips

Centre punch

Half inch spanner

Big spanner say about a 18mm

Flat head screwdriver

Hammer

Loctite

Beer

Remove boots, locate lock pins hit with a center punch and drill out.

Loosen off the lock nut and unscrew the rackend, use stilsons or big multigrips.

Next center the rack, use a ruler and check each side till you have it centered .

There is a shoulder in side that stops the rack at full lock, this is where the measurement is taken from.

Now that you have it centered make a mark on the pinion and housing for a reference.

You will need this when you reassembled the rack.

Can't see the marks that well in the picture, use either a punch or a file to mark it.

Next remove the preload bush.

Remove the retaining plate.

There will be shims in there a spring and the bush, you can get replacement preload bushes.

I reused the old one.

Next removing the pinion.

Remove the retaining plate , there will be a ring then shims a bearing the pinion a spacer and another bearing.

You will need to use a center punch in the hole in the top knock out the bearings.

If they go cockeyed they will wedge in and won't come out so keep them straight as you knock them out.

Pop out the top seal put it aside to reuse it, pretty sure you can still get them but it's not like the are under any pressure, just there to keep the dust out.

Put the pinion in upside down from the top to knock out the top bearing .

Next pull out the rack shaft , may need to use some force.

Then pry out the bush, I dislodged it with a screwdriver then just the rack shaft to knock it out.

Next clean all parts and inspect for damage , I painted the housing before assembly but you can paint after.

Check teeth , ball end on the rackends , bearings etc for wear/damage .

The best way to check the bearings is to hold in your palm and with other hand push with your thumb and rotate it , if it feels notchie it had pit marks in it. Should still be able to get them new, mine were good .

Time to put it back together .

First set up the preload on the pinion. Pack the bearings with grease, wheel bearing will be fine.

Top bearing spacer as in picture push into housing, then lower bearing fits opposite to the top sorry no picture then shims ring and retaining plate.

When fitted it should spin freely with no up or down movement and no side to side movement .

I set it up with all the shims that come out of it but it was too loose and I didn't have any more shims so I made one out of sheet metal, ended up not having to use all the shims after that.

You can see it sitting on the end plate.

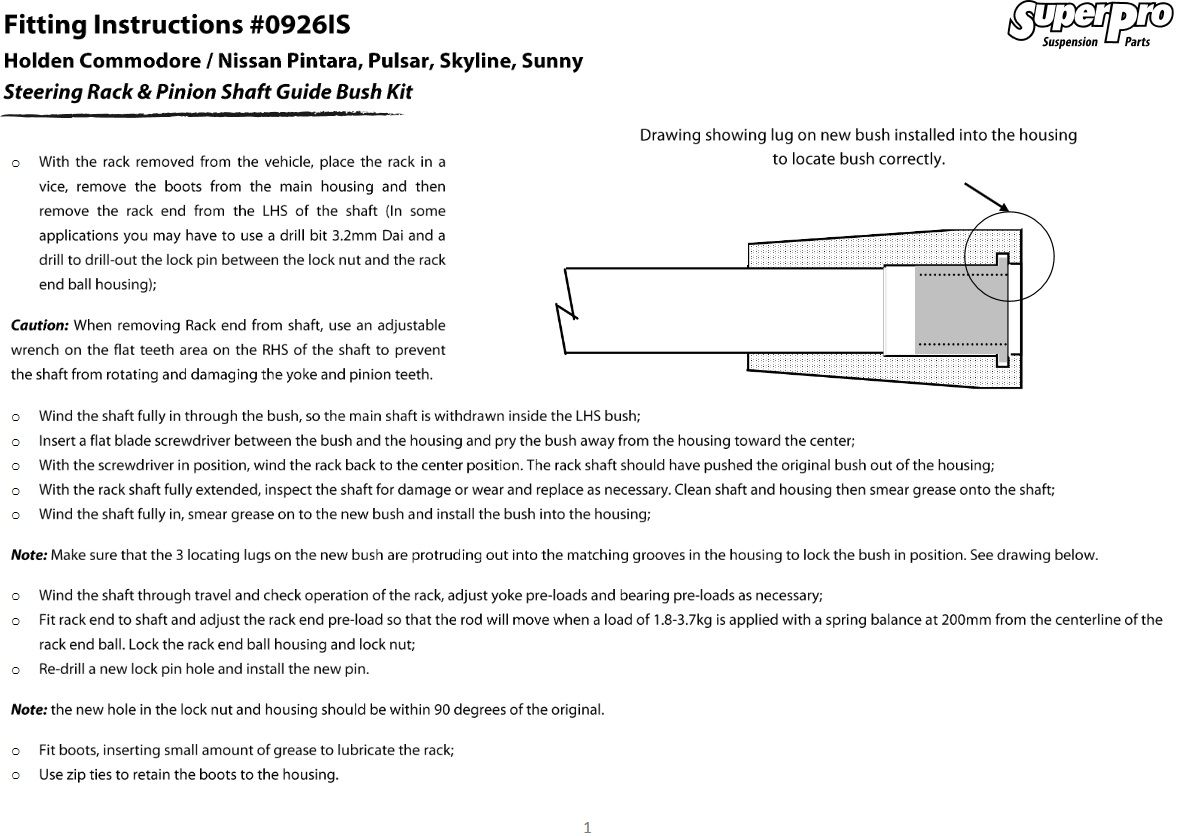

One that's done push in the new rack bush. There is little locating wings that sit in a groove in the housing, I used a screwdriver to locate it.

Next grease up the teeth and shaft, avoid getting any on the threads.

Push in the shaft from the pinion end.

Fit the lock nuts and center the rack shaft.

Now it's time to fit the pinion back in, that mark you made on the pinion, we want it to be 180° from where it was originally, this is so the worn area on the pinion is now not in the center point of the rack .

Setting up the preload bush.

I ended up using the same amount of shims that was already in the rack, I did remove the gasket with is roughly the same thickness as a shim.

One the preload shim is set up you want a small amount of movement, as in the picture you should be able to leavers the spanner back so the shaft will move about 2mm.

Rotate the pinion with vice grips, if it feels tight and notchie the preload is too tight, If it's loose and has free play its too loose.

Fitting the rackends, you can buy new ones but the old ones can be reused providing the ball end is still round.

Put in the cup end with washer and spring, use some grease to hold it together.

Fit into end of shaft.

Grease the end, don't get any on the thread .

Apply loctite , screw on.

You want to have it tight enough that it supports is own weight and has resistance when you grab it and move it around, then tighten the lock ring.

I would drill and pin like it was originally but I couldn't get the pins individualy, they still come in the p/s kits.

Alternately this is how big norm did his

http://fordcortina.com.au/newforum/i...64.msg7079#new

Now grease the rack some more, apply more to the teeth plus bush end by turning it end to end repeat a few times, also on the rackends

Fit your boots use zip ties and those little clamp things, fit the pinion seal and your done!

Reply With Quote

Reply With Quote

Connect With Us