I'm backtrackin'. Trust your engine builder, follow his advice.

That engine is sensational, well done.

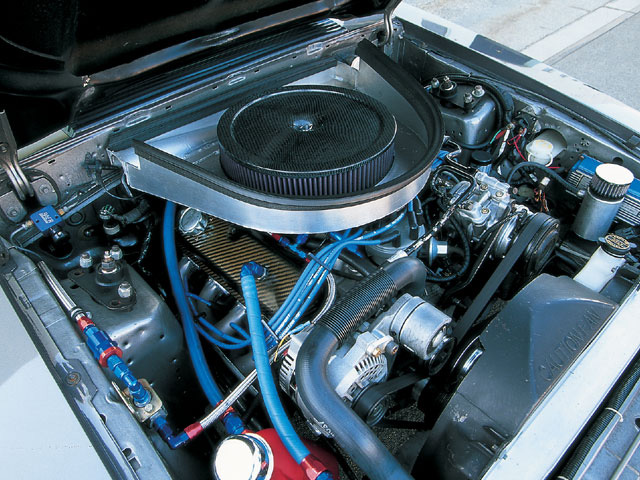

Your engine is typical of the best aftermarket systems; it will be noisy as it has no effective silencing with that free flowing cotton strand air cleaner, and "fumey" (there is no means of managing blow by which will certainly be more than 2 cfm at 4000 rpm).

So you'll hear and smell everything.

I'd be looking at Option 4, DV's Evacusump as listed in the two book related posts above. Or one of the lower tier options 1-3.

Don't beat on it too much until its run in.

Your engine will be making one hang of a lot more mid-range, and the oil and blow by and soaking might be noticeable at high rev's, but the top end could be being drowned at as little as 3500 rpm depending on cam type....your rocker covers don't have baffles. And they won't stop a bath of that much blow by related oil....

All fresh, out of the ordinary builds like this have non standard parts that don't have the standard details of a production part. Noise suppression, silencing, oil control via a Federally approved PCV system, none of it is there, its all just pure, no holds barred performance engine. And I totally approve.

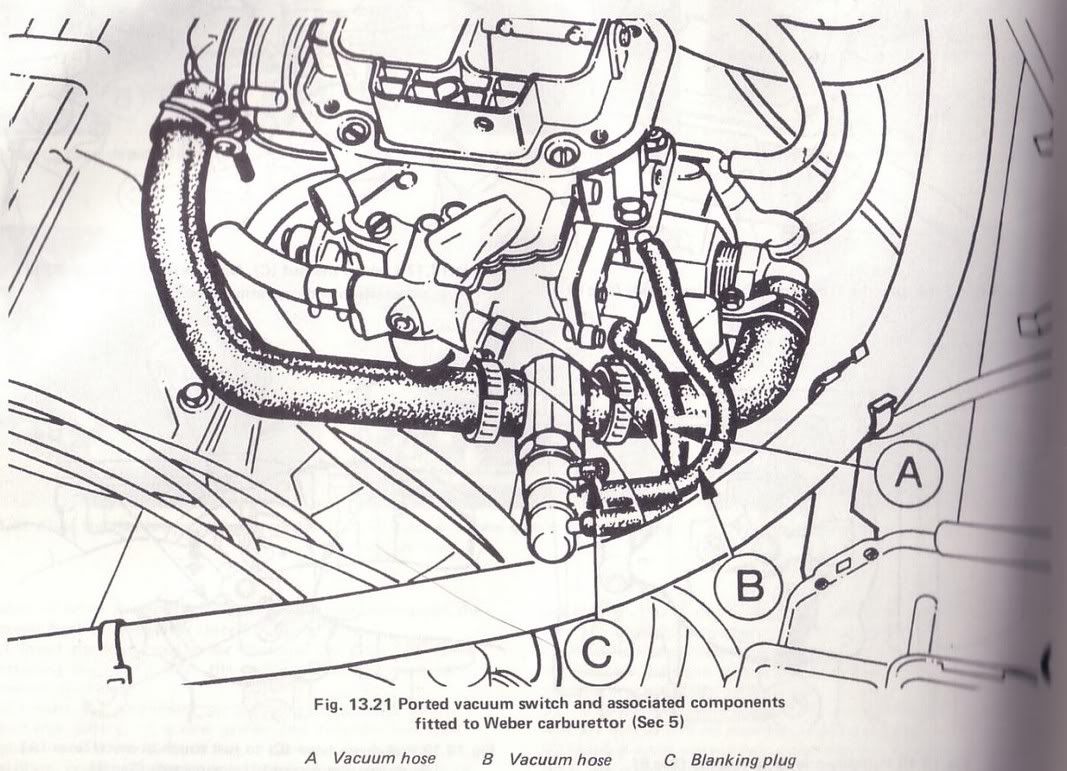

I've dealt with blow by problems on most new performance rebuilds....you fix it by going back to those basics. Factory style under hood snorkels, factory baffle under the PCV like most of the stock rock covers had, and a balanced PCV are a start.

One guy here has an Atomic EFI with a stock twin snorkel air cleaner with two variations. Stock twin snorkel drops out past 600 cfm, so his has larger pipes and two pancaked oval intake ports to the air cleaner....although it looses a little appeal, it aces the class for noise suppression and heat soak.

EFI engines really do produce the goods..a little more of everything. But you'll notice other stuff....

Reply With Quote

Reply With Quote

Connect With Us