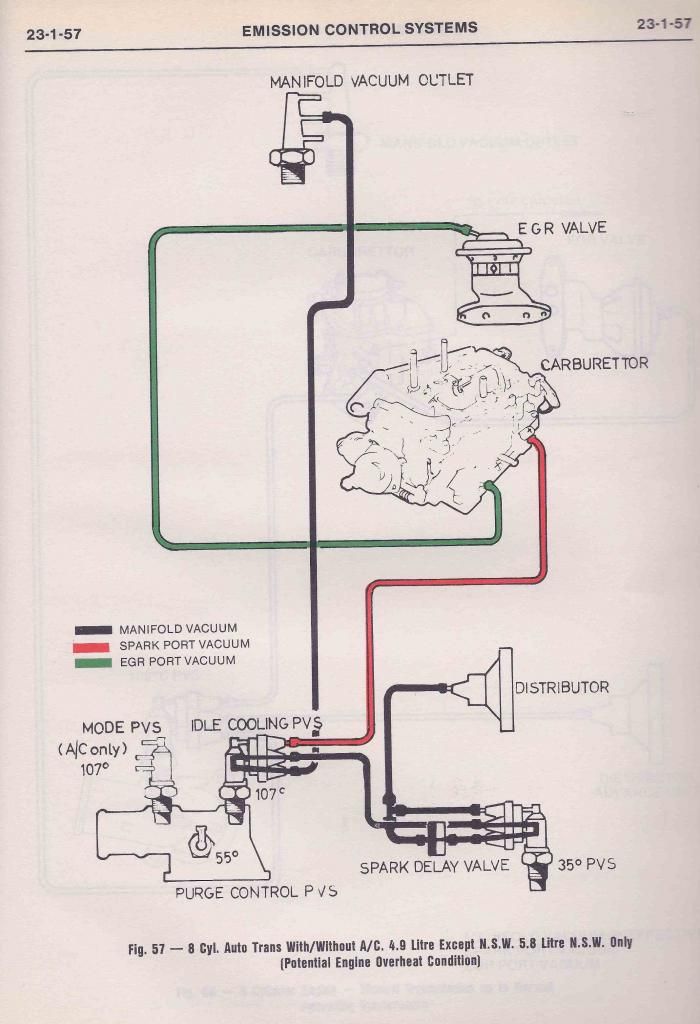

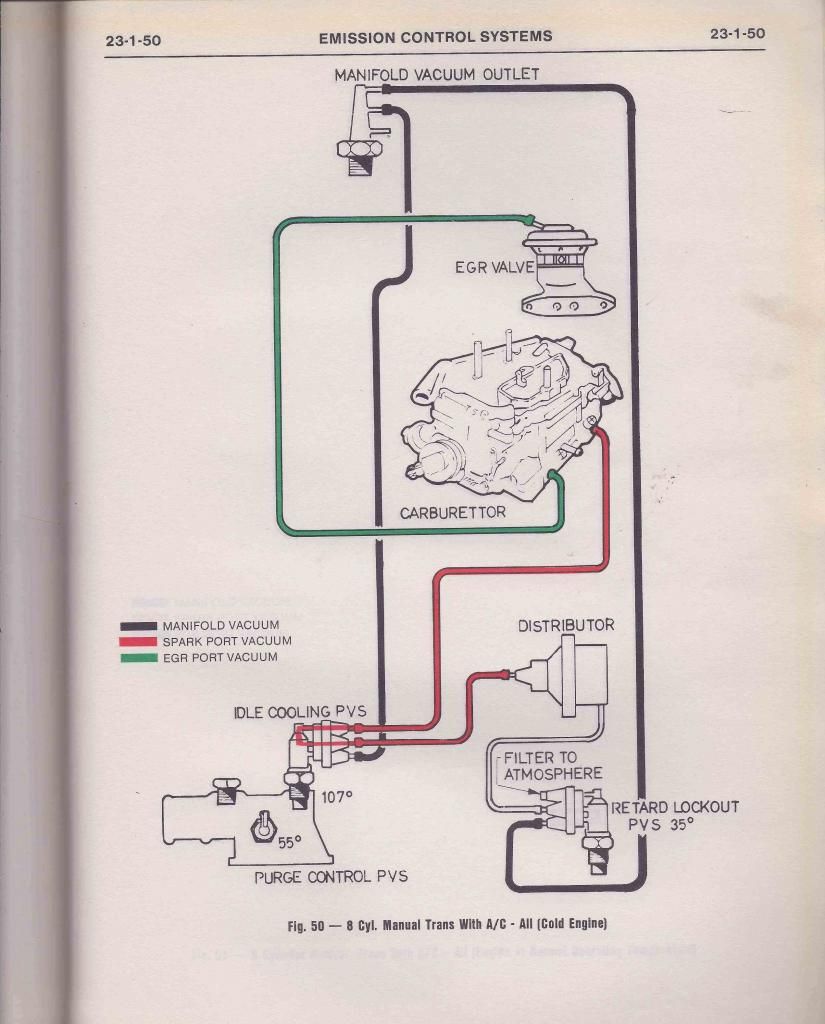

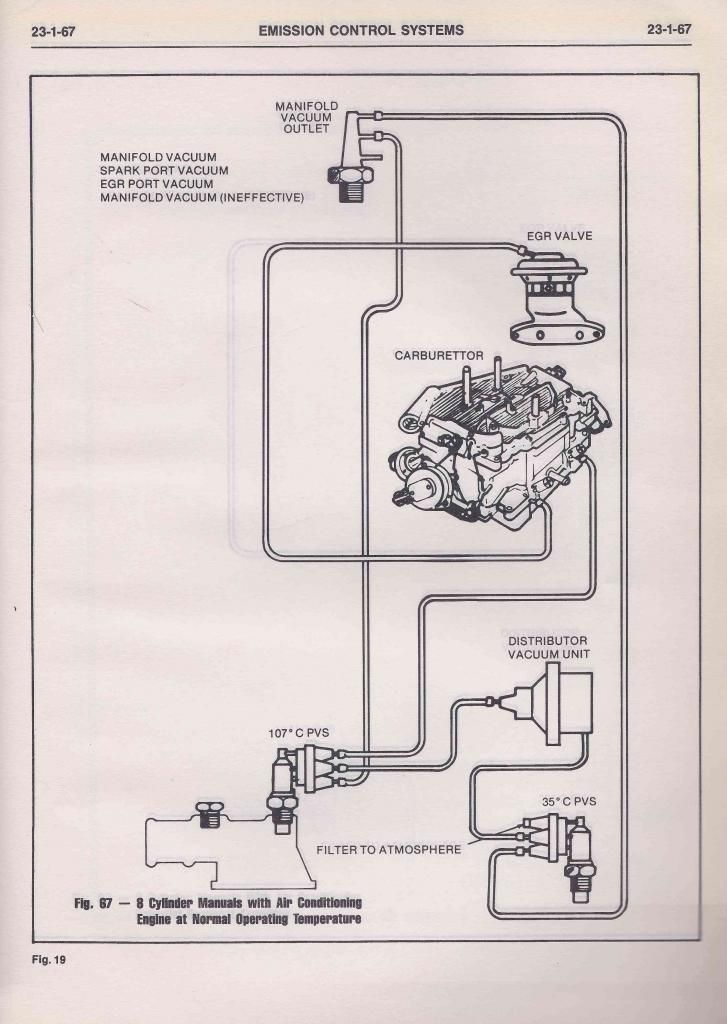

Ok, here's the skinny; my plan is to use my recently acquired '83 GT as a daily. As such, it will need to be MD emissions compliant. For vehicles prior to '96, this means tailpipe sniff of HC, CO, CO2, O2, and NOx at idle and 2500 rpm. I am considering SEFI, but would like to retain the dual snorkel air cleaner, so carb or tbi/cfi are my options.

Other than the stock 4180, or Edelbrock 1400, what aftermarket carbs have egr vac porting. If the answer is non, how tunable is 4180? I'm intimate with efi, and driveability in general, but the only carbs I have good knowledge of are the Autolite 2100s, CV motorcycle carbs, and related, the dreaded VV carb.

Engine plans are mild; roller block with stock roller HO can, 1.7 rockers on GT40 heads, full thermactor, egr and evap. Shorty headers and 2.5 duals with cats.

I've looked at the various tbi/cfi offerings, and if unable to find a satisfactory carb, I'll most likely build another MegaSquirt to drive a GM throttle body, and add emissions functions hardware and code.

So, any suggestions?

Reply With Quote

Reply With Quote

Connect With Us