Just got back from the shop - The look on his face and his reaction when he saw us walk in with another broker stud was amazement. "Another one?" he said. He was real concerned and was more than happy to swing by to see where things were. He's going to come over to Dads tomorrow to see what's going on.

Dad and I both feel much better - hopefully it's something stupid and an easy fix. My mind just gets going with every possible outcome and the worst case scenarios are usually at the top of the list.

Stay tuned!

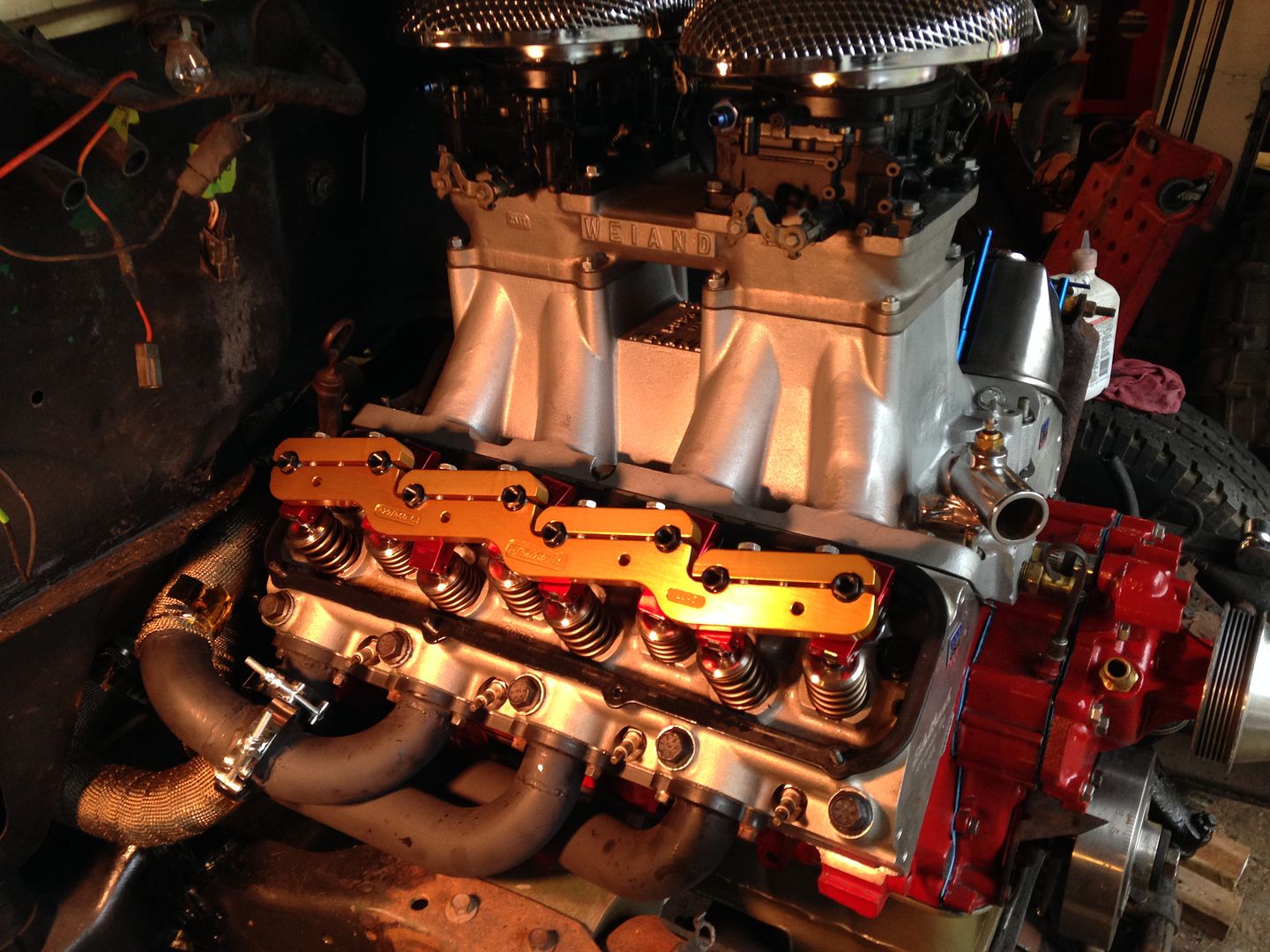

In the meantime - quick clip of the car after we fixed the first broken stud...

Reply With Quote

Reply With Quote

Connect With Us