I have been gone for quite a few months from this site. Mostly ghosting as I was involved in a different project. I have been rebuilding/replacing the Cleveland in my 73 Mach 1. I took lots of pictures and thought you guys might want to see something a little different. Let me know what you think. I'll be throwing up pictures, and updates every few days as there is a lot of it.

I figured I'd start off at the beginning:

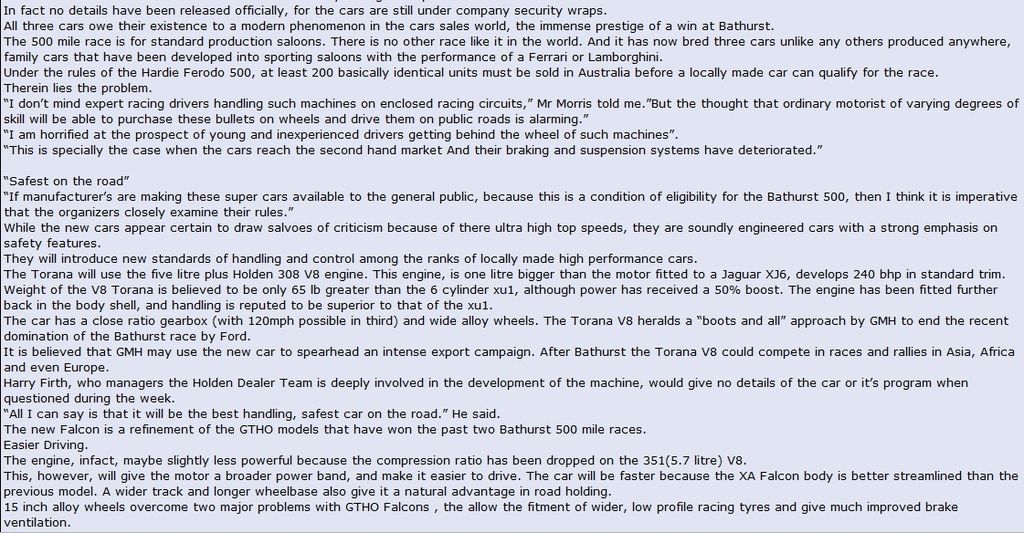

A while back I picked up what I hoped was a good block for my new 351c build. It is an Aussie 351c and has some interesting differences. "D2 E-CA" block casting. Casting date has it as a 1977 and we know in the USA they stopped making Clevelands in 1974. The main caps are different as well. No less beefy but they have a different looking set of numbers and directional arrows.

This one already had some quality machine work and upgrades. Deburred, o-ringed, .030 over, Aussie crank was standard/standard and the bearings look perfect. Connecting rods have been rebuilt, beams ground and shot peened. I believe they are Moroso rod bolts as they are not stockers, but do not have ARP on them. They do have the stretch gauge alignment dimples. Balanced rotating assy. Has the Moroso oil restrictor mods. Bores look awesome and the rings are perfect. I doubt this engine has seen 500 miles. Tight Rollmaster timing chain that I will be reusing. I put the carbon'd up pistons in my ultrasonic cleaner and they came out like new. Didn't even need to take the rings off. I love that thing. The only downer is the pistons are cast Silv-O-Lites.

The new/old 4V quench heads that I ported are at the machine shop. I' was doing a lot of talking with the machine shop and my Camshaft guy, trying to nail down a valve train combination.

Piston as they came out of the shortblock

One cycle through the ultrasonic cleaner

Two cycles

After the 4th cycle

Rods with polished and shot peened beams

Reply With Quote

Reply With Quote

Connect With Us