Hey guys

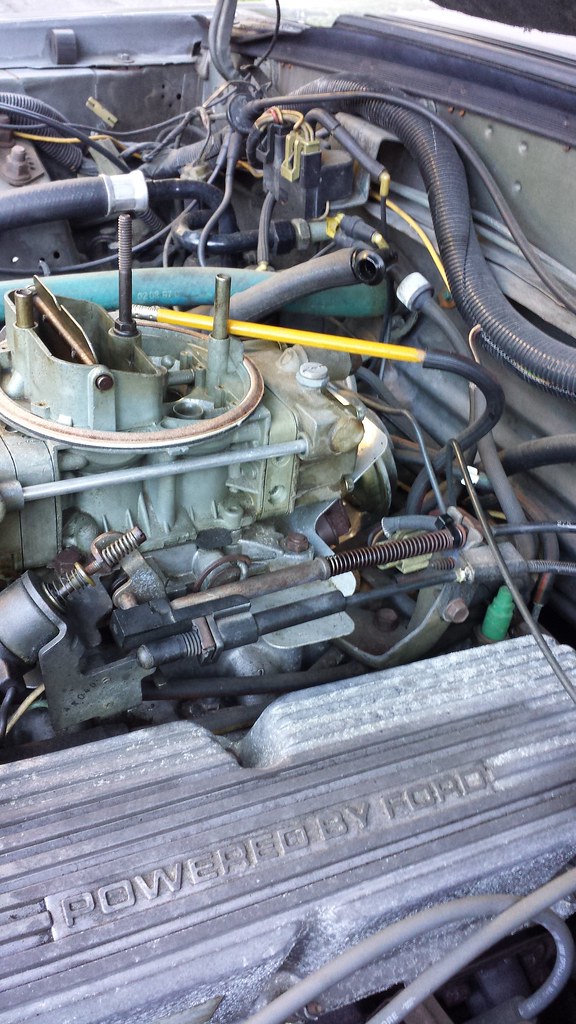

I have a stock 4180C with the secondary metering block mod. The car runs great and idles smooth.

What's driving me crazy is the idle. Something is holding it up and keeping it from dropping down. I'd say it's been an issue for a while (on and off over the course of the last couple years). It seems to only happen when the engine is fully hot. I know there is a system to increase the idle to help keep the fan speed up to cool the car, but this is higher than that. Not to mention, it's been in the 50s or 60s when this has been happening, so that system shouldn't even be in effect. Normally, I cure the condition by lubricating the throttle linkage and hitting the throttle spring and stuff with a little PB blaster.

Unfortunately, now most recently the car has been idling even higher, and despite doing my usual routine and even blasting everything clean with carb cleaner, it still holds itself up.

The normal idle is set to 700rpm after the choke is pulled off. When the car is started, it runs on fast idle, and the choke completely pulls off as it should down to the 700rpm idle.

After driving the car a little and getting the engine up to full temp, I notice the idle is holding at about 1000rpm after pulling up to a light. I can blip the throttle and get it down to about 850-900rpm. If I lightly press the accelerator and raise the rpms up past 1000 and let it go, it will hold again at 1000rpm until I blip the throttle.

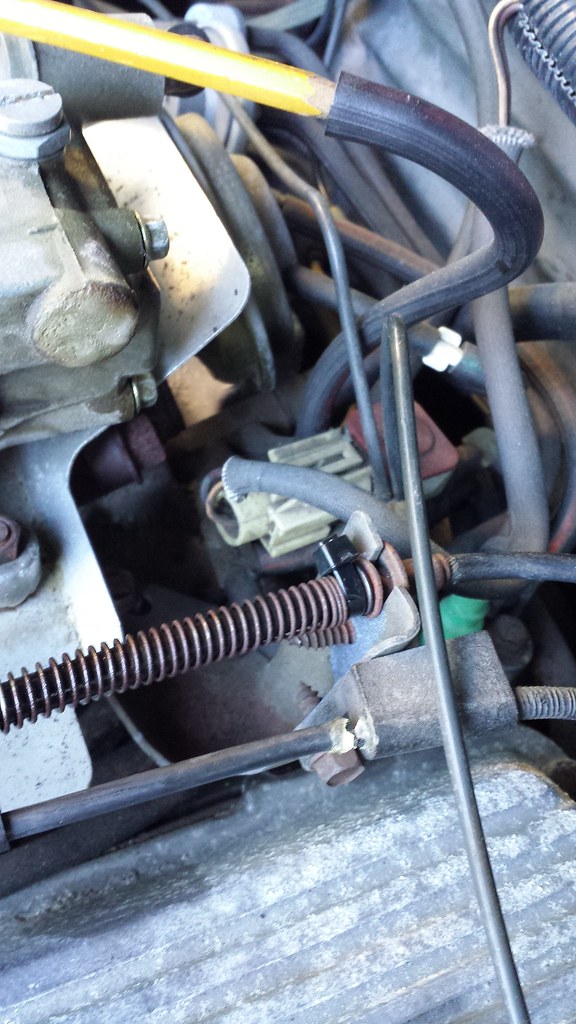

I can physically push the throttle pin down while the car is running and get the idle down to 750rpm. I can see that there is like 1mm or less of travel in the A/C solenoid that the throttle can't seem to compress when the car is running. While off, it seems to compress fine. ???

Additionally, if I physically push the secondaries closed while the car is running, the idle drops completely down to the expected 700rpm. This only seems to happen when the car is running. Starting the car from sitting (even hot), the idle is normal until the car is driven.

I hope this all makes sense. It seems very touchy. And it's going to drive me insane soon if I can't figure this out. Is this a physical throttle / binding issue or is this a vacuum issue??

Thanks

Reply With Quote

Reply With Quote

Connect With Us