In the very early 1960s, Engine Engineer, Ed Pinkerton, worked for Fordís ĎScientific Research Organisation,í located opposite the EEE building on Oakwood Boulevard, where Car Styling and Body Engineering was housed, which afforded him the opportunity to work on various theoretical and practical engineering matters, beneficial to the companyís future projects. Ed Pinkerton carried out significant experimental work, in order to separate fact from fiction, and to determine the ideal connecting rod-to-stroke ratios, in a quest to obtain optimum engine efficiency. Much of his investigation involved a single-cylinder test engine, and, later, the FE NASCAR engines, resulting in the production of a range of interchangeable connecting rod and piston combinations, specifically for these tests. The sets of connecting rods were approximately 0.030in/0.75mm different from each other, in centre-to-centre length. They were used in conjunction with pistons, with the gudgeon pin re-positioned to compensate, allowing the overall piston crown to remain constant. Using the same two cars and engines, all combinations were track-tested, resulting in irrefutable conclusions.

The 1.68:1-1.72:1 connecting rod-to-stroke ratio combinations worked most effectively, and although the horsepower and torque remained more or less constant for all engines, there was a significant difference in the rate of acceleration off or out of a turn in a test car.

The problem with connecting rod-to-stroke ratios larger than 1.72:1 is that, as the combustion pressure increases when the piston is at top dead centre and just past it, the connecting rod is technically pushing down vertically onto the crankshaft. The longer the connecting rod, the longer the time it is effectively too vertical, and, as a result, the combustion pressure energy is not being used to maximum efficiency to turn the crankshaft in the direction of rotation; essentially it is trying to push the crankshaft out of the bottom of the engine.

The experiments carried out by Ed Pinkerton concluded that, generally, for all current Ford engines, a connecting rod centre-to-centre distance to crankshaft stroke ratio between 1.68:1 and 1.72:1 was the requirement, with the latter regarded as optimum. The centre-to-centre distance of the connecting rod is divided by the stroke of the engine, which is sometimes referred to as the ĎL over Rí of an engine. Pinkerton noted that if the connecting rod-to-stroke ratio was less than 1.68:1, this factor did not necessarily result in an engine lacking responsiveness, however it did start to affect the piston skirt service life; the shorter the connecting rod, the higher the rate of piston skirt/bore wall wear.

Ford sometimes went beyond the ideal connecting rod-to-stroke ratio of 1.72:1 for other reasons, notably for the 1969 and 1970 Boss 302ci Trans-Am racing engines, that used its Indianapolis racing engine connecting rods, with a 5.312in centre-to-centre distance. This was coupled with the 3in stroke, which, quite coincidentally also resulted in a ratio of 1.77:1. In this instance, it was exceeded to keep the piston weight down, as 0.157in of connecting rod ĎIí beam cross sectional area weighed less than 0.157in of aluminium piston skirt mass, but, this ratio was regarded as the absolute upper limit. In the 1960s, car engines were not reaching such high rpm levels as today, where current NASCAR V8 engines are turning 9000rpm, and, based on experimentation and the subsequent results, all have connecting rod-to-stroke ratios in the vicinity of 1.77:1-1.81:1.

To increase the capacity, nowadays, various types of long-stroke crankshafts are fitted to V8 engines, and as a result, the connecting rods are becoming shorter and the pistons designed more squat to fit into the block. Although this procedure is quite acceptable, due to the loading, the bore wall and piston skirt life can be greatly reduced. Therefore, it becomes a matter of obtaining a larger capacity with a reduced service life expectancy over stock, and possibly, an engine with less than ideal engine performance characteristics.

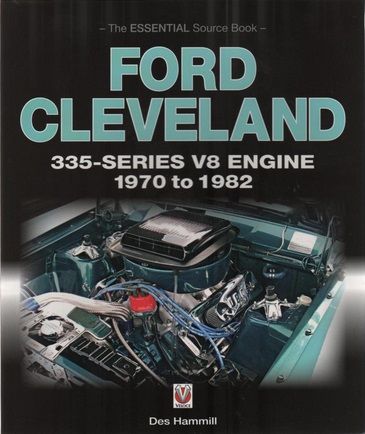

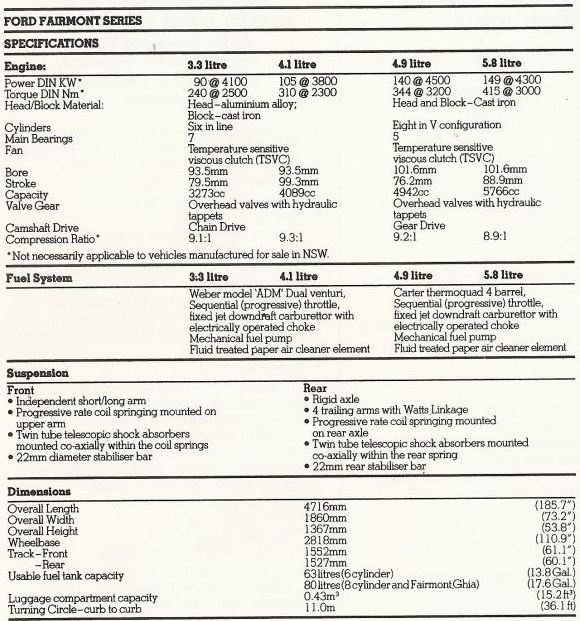

The original low-deck USA-made 1970-1974 351ci-2V and 351ci-4V engines used 5.778in centre-to-centre distance length connecting rods, as did the Australian-made 351ci-2V and 351ci-4V engines between 1972 and 1982. However, the 302ci engines manufactured at the Australian Geelong Engine Plant between 1972 and 1982 used components with a centre-to-centre distance of 6.020in, specifically to allow them to employ the 351ci piston.

This move, while allowing Ford Australia to use a common part, reduced engine performance capability, as the connecting rod-to-stroke ratio was well above the ideal range.

When the 351ciM-2V engines came on stream in the mid-1970s, they were used to power trucks and many cars. Mrs Lee Iacocca had a car fitted with one of these engines which cut out on the over-run, leading up to a roundabout. When the engine stalled, there was limited power assistance for the steering, and she careered straight over the roundabout and into a fruit stall in a market place, before coming to a halt. Fortunately, no one was injured, but on hearing of the accident her husband, President of Ford, Lee Iacocca, demanded the problem was fixed immediately, as it was unacceptable for expensive Lincoln cars to stall in this way.

Engine Engineering engineer Bill Barr was assigned to investigate the problem, and when testing the cars, c

ould not believe how sluggish they were in comparison to the earlier USA 351ci Cleveland engines. He subsequently made enquires into the differences between the two versions. When he was given the data, he recalled remarks made by Ed Pinkerton at a lunchtime discussion in 1963, during the Indy engine programme, regarding connecting rod-to-stroke ratios. He noted the long connecting rod aspect of the 351ciM-2V engine and extra weight of the internal components, in comparison to the 351ci US Cleveland. The connecting rod-to-stroke ratio of the USA 351ci Cleveland was 1.65:1, versus 1.88:1 of the 351ciM.

For low-deck block 351ci racing engine applications, changing the original stock-connecting rod centre-to-centre distance length from 5.778in to 6.020in, in conjunction with the stock 351ci stroke, results in an increase in a ratio from 1.65:1 to an ideal 1.72:1.

Connecting rod-to-stroke ratios

Engine Connecting rod-to-stroke ratio

302ci low-deck 2.01:1

351ci low-deck 1.65:1

351ci tall-deck 1.88:1

400ci tall-deck 1.65:1

Reply With Quote

Reply With Quote

This will be interesting...

This will be interesting...

Thanks for that.

Thanks for that.

Connect With Us