New guy here starting my 79 wagon build. I'm doing a few things that have never been done before to my knowledge and hopefully I won't get kicked off of here. Lol. I know there are a lot of purists but I think I have a pretty good vision for a cool wagon.

The story: I found this wagon local that was a hacked up drag car only with some really ****ty workmanship all over it. Gutted interior, all lexan, terrible cage, patch panels laid over rust, bad body work, etc. I picked it up and I'm going to get this thing back to where it needs to be with a full rotisserie build.

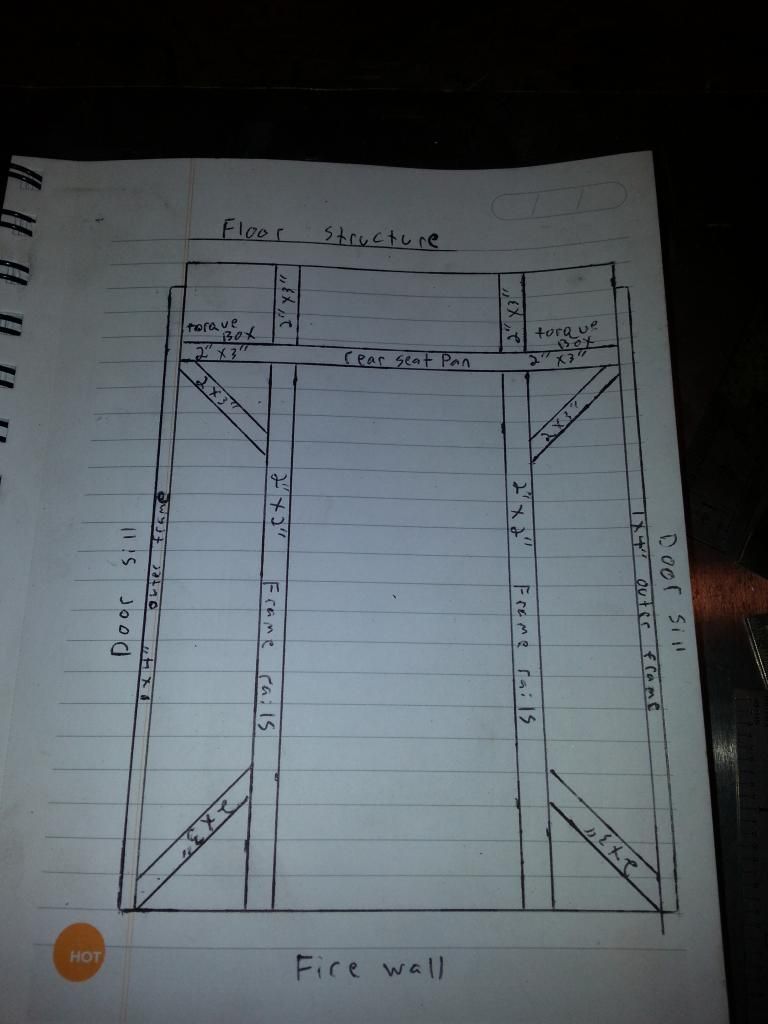

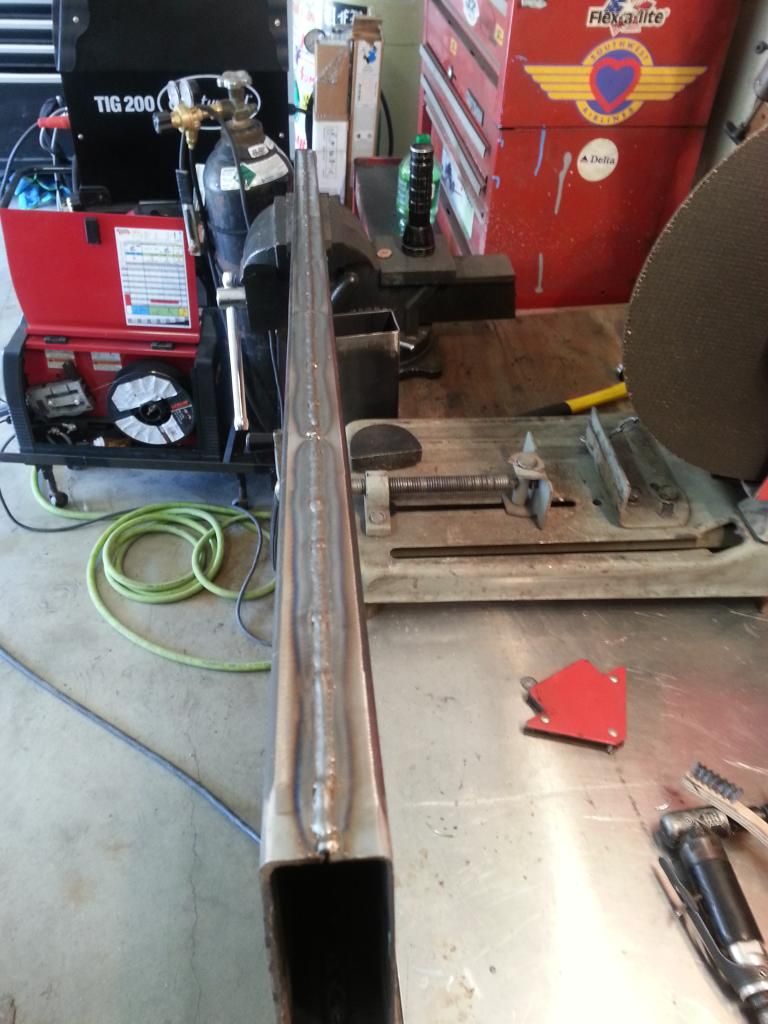

The plan: I've got a sbf dart block 428 stroker setup that's starting to come together now. I've got a callies billet crank, Lentz billet rods, dart 9.5" iron eagle block, 7721 heads, and a blower manifold. It'll be receiving a 14-71 blower and holley hp efi and should make in the neighborhood of 1600hp while retaining streetability. I'll be reinstalling all the glass, stereo, sn95 interior, a.c./heat, and a full flour pan from a 97 mustang cobra parts car.

Cobra parts car for the interior and floor pan. Car had no title so it was as good as trash. My friend was kind enough to sell me the parts I needed if I pull them.

The wagon parts car that I pulled all the interior from asking with glass and doors.

This one had no title and no floors at all from rust. Sad to say she went to the scrap yard when I was done. It just couldn't be saved. Parts will live on in my other wagon though.

Reply With Quote

Reply With Quote

Connect With Us