Isn't it funny when as a result of either catastrophic failure, defect, or ignorance on the part of the installer, after having to go through the effort involved, and the time to tear the stuff apart, you are some how happy that you

found broken, or screwed up junk?

Such was the case this afternoon.

I was telling the wife about the dilemma. No, scratch that.

I was Bitching to the wife about the leaking piece of junk head gasket, and told her that i was gonna wait to tear it down till after I spoke w/ SCE tomorrow to see what he tells me. The wife asks real matter of factly....."Why?"

"Why what?" I responded. "Why are you waiting,...Aren't you gonna have to tear it down anyway?" She asks.

"Well,...yeah, I was just waiting till I got my mind around it." I replied.

She says "Sounds pretty stupid if you ask me, how is it gonna be any different once you "get your mind around it?""

I went down into the garage.

I started on it at 5, I was done w/ it by 6:30. (Stuff always comes apart way faster than it goes together)

Oil everywhere.

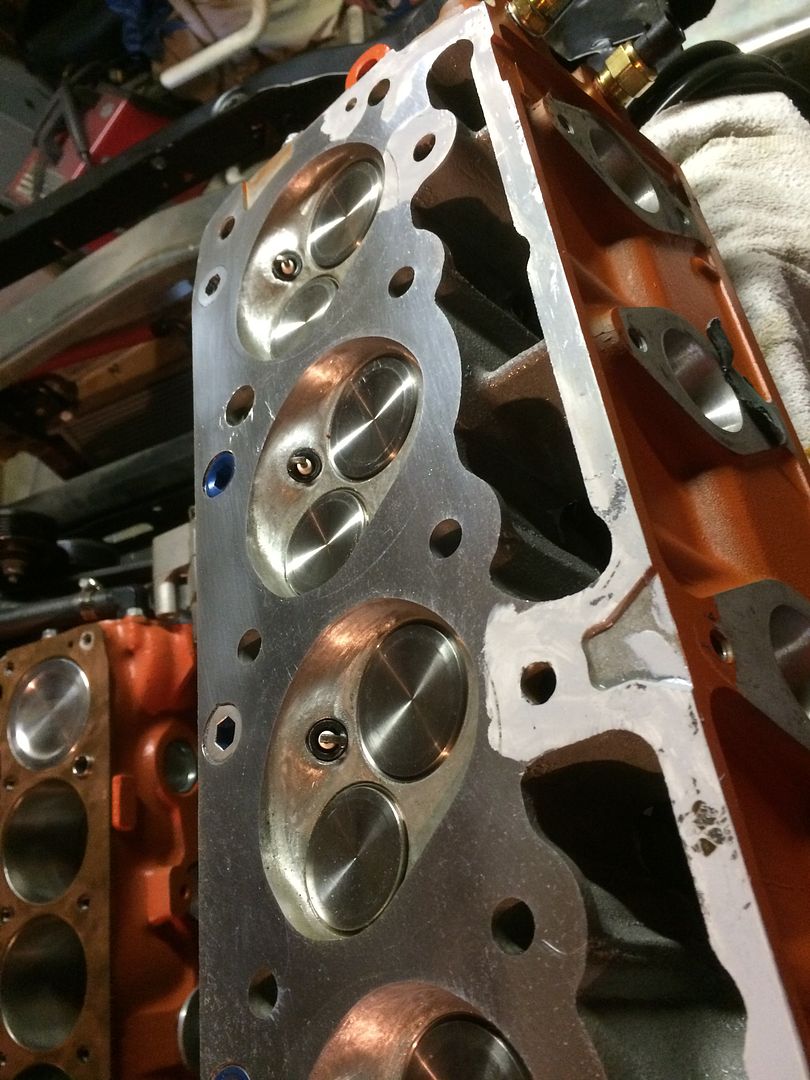

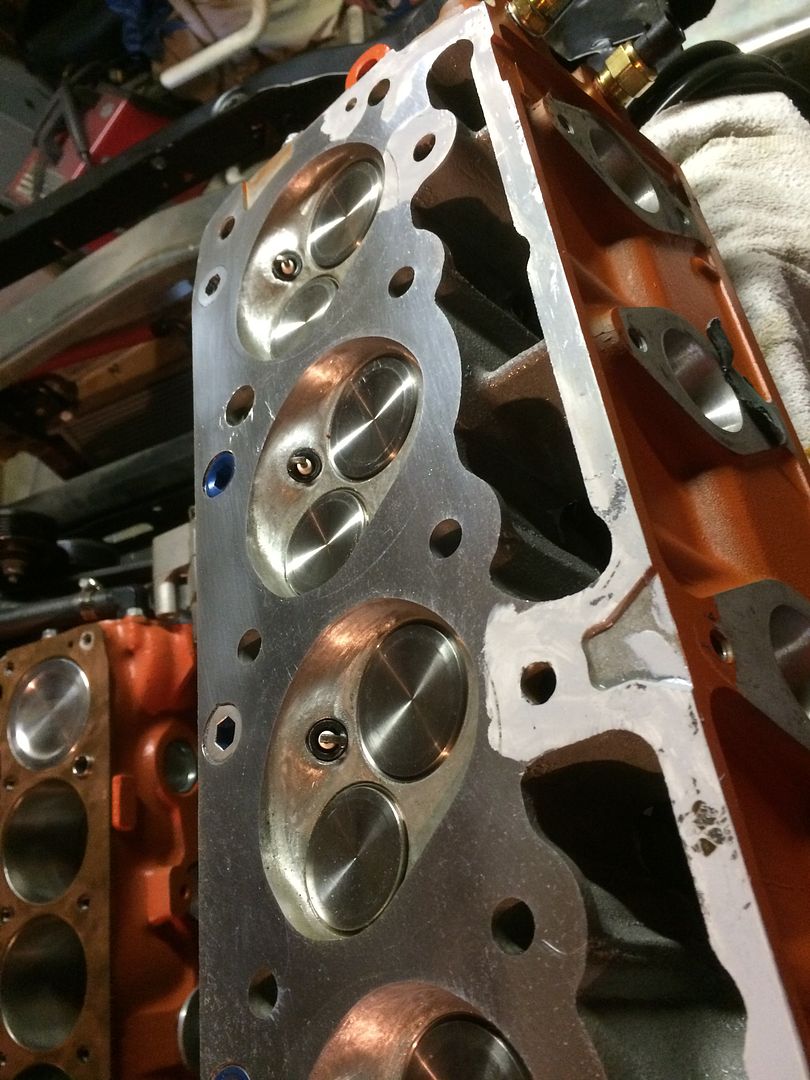

The bluish stuff is Hondabond. Looking at the pic shows that Mike screwed up. He didn't think to seal the inside of the lifter galley. (But then again I figured that oil would find its way back into the engine on the

inside)

I'll take credit for that, what I want to know is how then did it get outside? That bead of Hondabond was on both the head surface, and the deck on the

outside But the oil that is on the opposite side drained down the head bolt bosses and found its way between the gasket and the mating surfaces.

Because there isn't any O-ring set into the block, or a receiver groove cut into the head, I bought a special gasket from SCE that has a wire ring sandwiched between the layers of copper, You might be able to see where that O-ring "printed" the head.

Know what I'm thinkin' though? I'm thinkin' that O ring held the head off the deck far enough to not allow the sealant to do it's intended job. Either that, or the thin, "skim coat" layer of Hondabond wasn't thick enough.

Oil is everywhere though, It was just as wet under this gasket as it was on top. I don't know what to think.

The problem w/ the Hondabond, is that it dries in a minute. By the time you get the deck coated, it's already dry where you started. Do the head, and by the time you're ready to set it, it's all dry. I'm thinkin' I want something that stays tacky for at least long enough to get it assembled. In retrospect, I'm thinkin' I don't want to have to put any sealer on the damn head gasket at all. I looked at the MLS gasket that I can have built. I'm concerned that where they'll have to add holes for water passages into the head, there won't be any provisions for sealing, like the embossed ridge you see on the outside edges.

Potential leaks if you ask me.

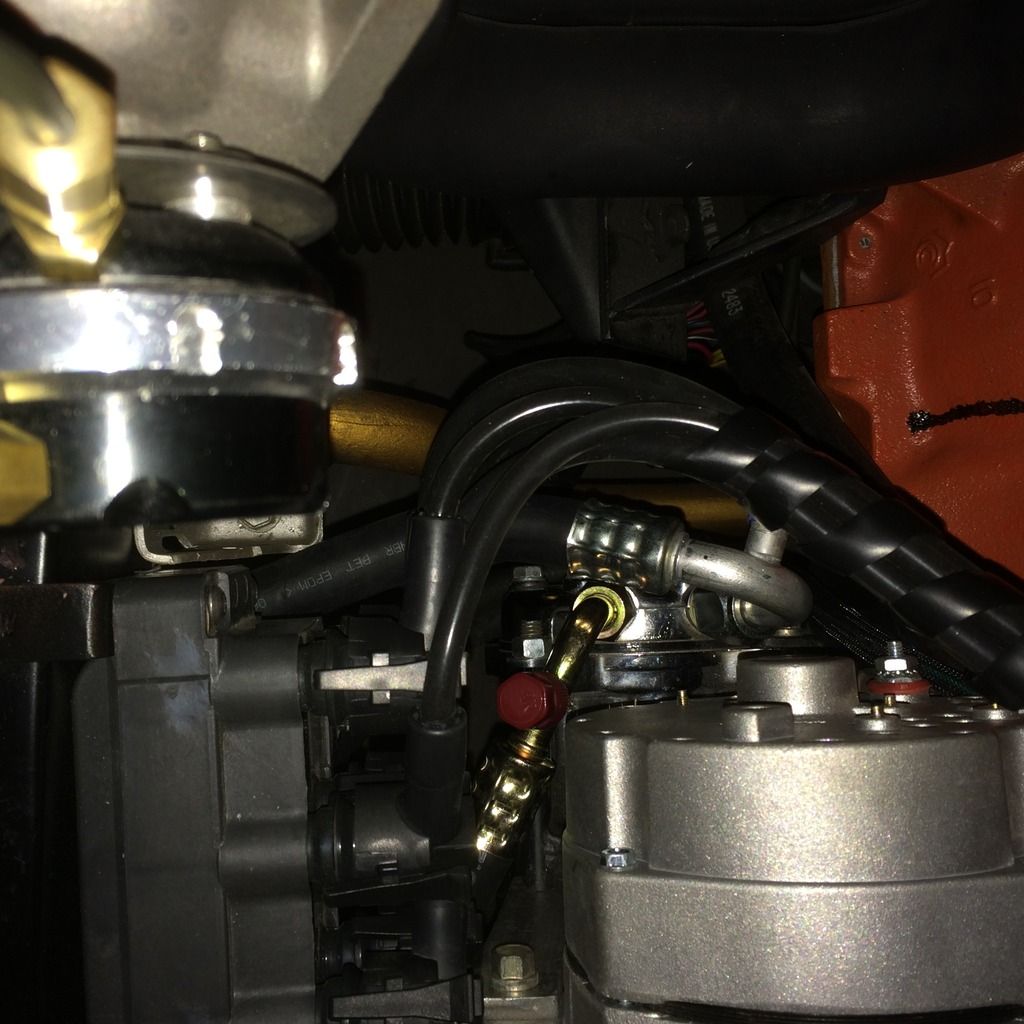

I did take a pic of the -12 that feeds my oil pump. I'm thinkin' I'm screwed w/ that set up. My only hope is that right now w/ 6 qts of oil in there, and the oil still isn't touching the top of that kick out, Maybe if I add another qt, it'll force oil up and out based on gravity...

only this time I'll take it to Oreillys, where they'll charge me as much to make one hose as my guy did to make 5.

Connect With Us