I'm avoiding the big long range tank just now. I joined an Ecomodder site, and have decided to bring up the fuel economy first, keeping the car as close to stock as a person can. Given its historicala nd truly odd ball JDM status and its value and its numbers match food chain position on the Fox family tree, I owe it to myself and others here to work with the orginal parts. Where I draw the line is with carbs, cam and tunining, for everyone in the past, from Holman Moody to Offenhauser, from Vic Edelbrock to Ak Millar enterpises, has had a go at Triple Carb economy Falcons and Mustang sixes, but they dropped the ball when the little I6 Foxes came out. And thats why the 2.3 and 5.0 and latter Essex and Cologne V6's survived, and the I6 didn't. It was too hard to hi po this ancient engine without a full head redesign, and Ford, probably wisely, spent the extra dough on better engines. Where I come in is that I'm stuck with the log, and I gotta just make it work within the confines of my budget and purpose.

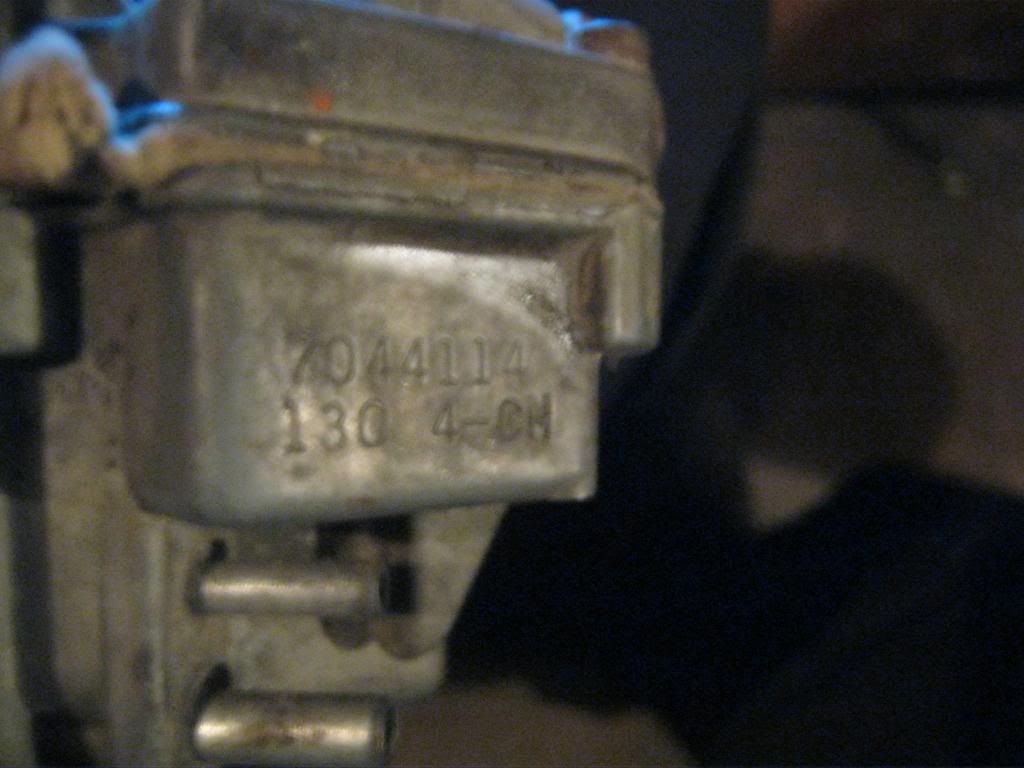

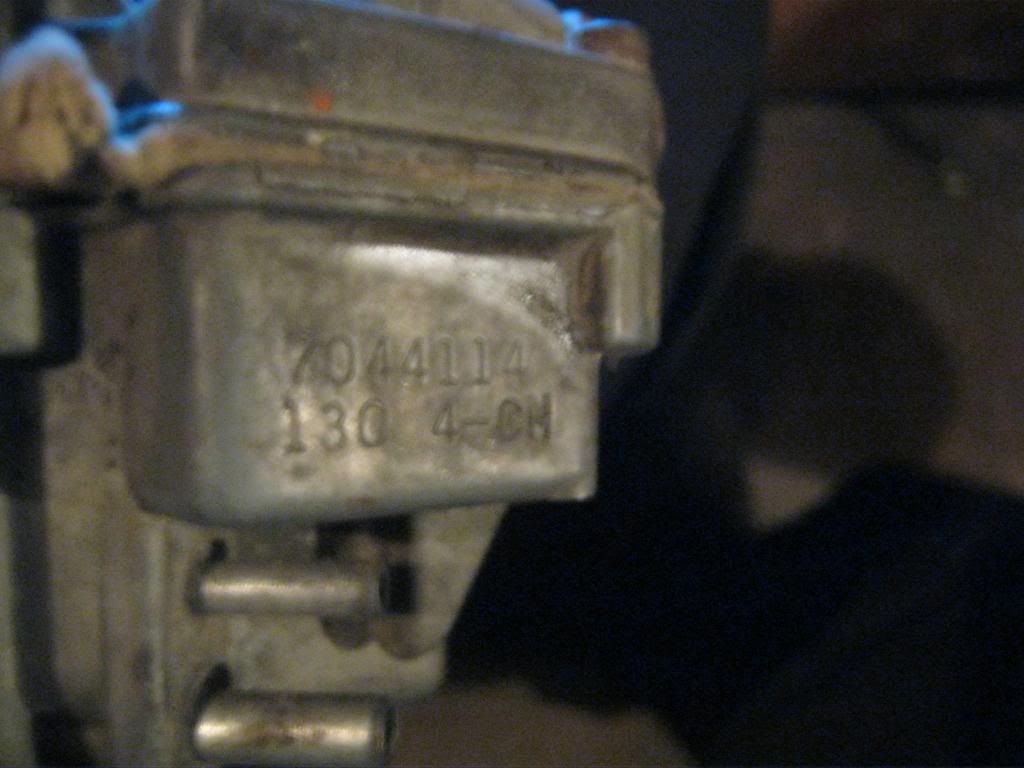

In line with that, I've been busy cleaning up my triple carb Rochester 2 jet carburation system for attaching to my 170 cylinder head. I'm using the common 7014114 130 4 - CM and P-7046452 C-1 code 2 Jet Rochester body 352 cfm carb,

Its a nice sized carb, good for independent runner induction, with 500 CFM Holley 2-bbl 4412 sized throttles at 1-11/16-in. bores, or 1.6875" or 42.8625 mm, and the same throttle center spacings as the bigger Holley 2-bbls (1.875" or 47.625 mm), but nice, small 1-3/16-in. venturis (30.16 mm) for that 352cfm at 3.0"Hg in each.

Where it is

heaps better than the good old 2100 Autolite /2150/Motorcraft and the Holly 2-bbl 7448/4412 part number 2300 series is for its four bolt clamping spacings, for even though mine is a wide base 2.0" by 3.75", its got heaps of room around it to mount in the confines of the awkward 200/3.3 log heads iron dog turd.

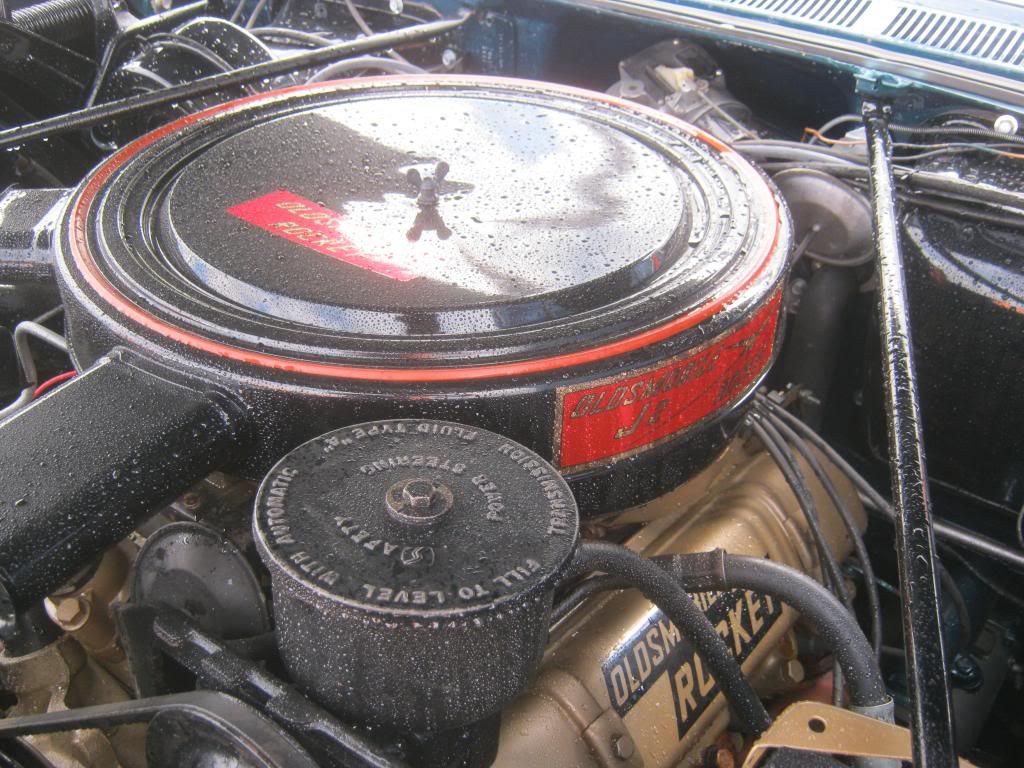

Once I've got these jetted down to the right level, I'll get the economy and power I'm looking for, and I'll be able to fit a stock Tripower air cleaner on it to ensure I can run it as an CAFE/CARB/EPA emission era system with all the stock interconnects.

Reply With Quote

Reply With Quote

oh man!!! that driver had better be supplying the beers for awhile!

oh man!!! that driver had better be supplying the beers for awhile!

Connect With Us