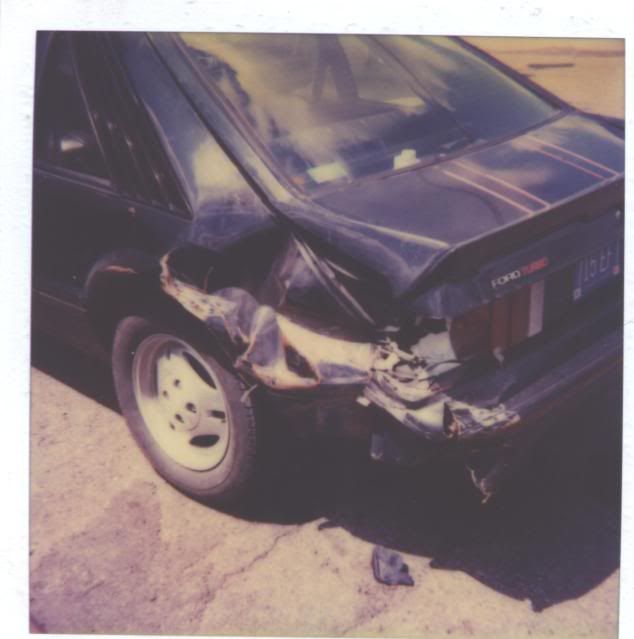

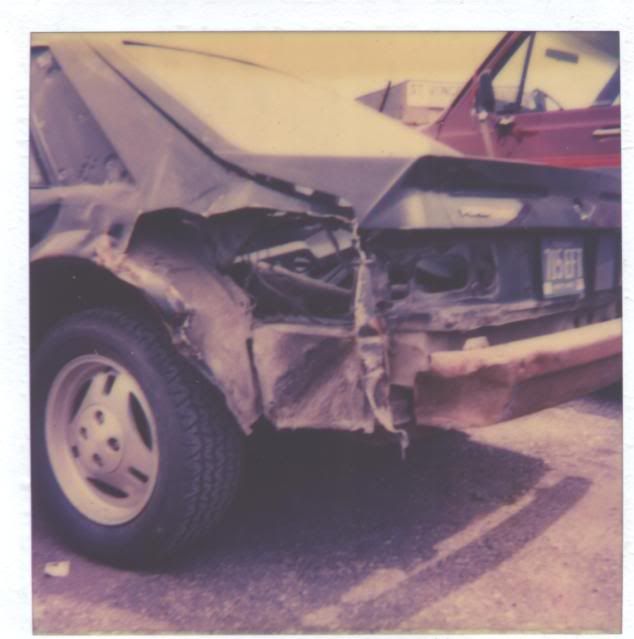

Okay, to start out I know I am on a 4 eye forum forum and I know that I have a 90 LX which isn't a 4 eye, but before you move my thread or yell at me for posting in the wrong place hear me out lol. So my 90 suffers from the dreaded car cancer, but not in a conventional way. Before I got it, the previous owner decided to put a GT spoiler on it and not fill any of the holes in the hatch. This cause all of the water to run to the sides of the hatch area floor (over the frame rails) and cause them to rust. The passenger side frame rail is solid (just surface rust and pitting, no holes or rot) however the driver's side didn't fair so well. The back portion is pretty rough as well as a small area of rot down by the torque box where the bolt goes through to connect the driver side LCA to the torque box. The reason I posted in the classic section is because a lot of you guys know how to deal with rust and I'm trying to see what I can do to fix it thus the response of "find another car" is not helpful and that seems to be the tendency of the 5.0 section. So here's a couple of pictures, sorry if they're not the best a lack of a lift makes it hard to get under and get good pictures. So what are you opinions?

This is from the inside down by the torque box.

Reply With Quote

Reply With Quote

That is some nasty rust there! I think the suggestions above are good ones. The biggest question for you is do you have the time and skills to fix this yourself. If not, do you have a buddy that is willing and able to help out. If the answer to both of the questions is NO, then I don't think you are going to be able to repair the rust at a low enough cost to justify it. At that point, I would look for a 4E that needs a good drivetrain and suspension and swap everything over!

That is some nasty rust there! I think the suggestions above are good ones. The biggest question for you is do you have the time and skills to fix this yourself. If not, do you have a buddy that is willing and able to help out. If the answer to both of the questions is NO, then I don't think you are going to be able to repair the rust at a low enough cost to justify it. At that point, I would look for a 4E that needs a good drivetrain and suspension and swap everything over!

Connect With Us